Air Emissions Calibration Testing: Staying Compliant With Daily and Quarterly Requirements

Accurate air emissions calibration testing is essential for maintaining compliance and ensuring reliable CEMS performance. This blog breaks down daily and quarterly calibration test requirements, explains how offline calibrations are used, and clarifies what causes out-of-control data.

CEMS Probe Maintenance: Extractive vs. Dilution Systems

CEMS probes are the first point of contact with the gas sample line in your emissions monitoring system. Discover why routine maintenance is critical—and how to do it right.

Where to Install CEMS Probes, Flow Sensors & Opacity Monitors (According to EPA Guidelines)

In this article, read about where you can locate your plant’s CEMS Probes, Flow Probes & Opacity Units on your stack unit & what EPA regulations apply to them.

CEMS Filter Maintenance Tips for Reliable Performance

Regular CEMS filter maintenance is one of the easiest, and most effective, ways to ensure accurate emissions data and keep your system running smoothly. This article covers why filter care matters, and best practices to keep your system running smoothly year-round.

CEMS Fails From the Field: What Went Wrong & How to Fix It

Discover the top causes of CEM system failures and how to prevent them. Get expert troubleshooting advice and maintenance strategies to reduce downtime.

Continuous Emissions Monitoring 101: Calibration Gas & Requirements

This article will discuss and clarify calibration gas requirements for CEMS users including, system calibration, cal gas bottles, and more.

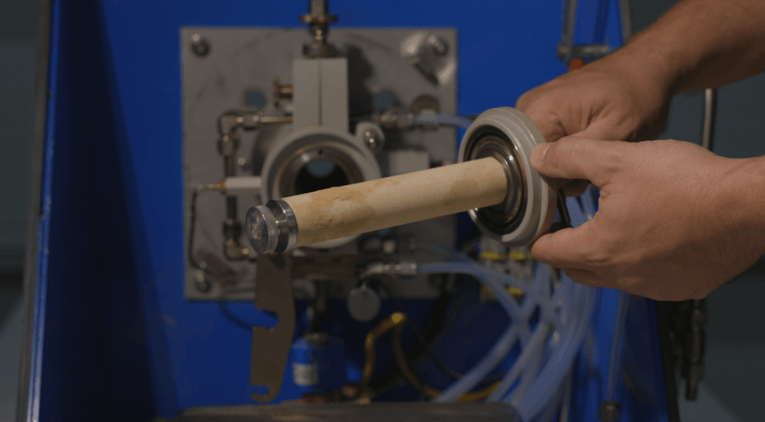

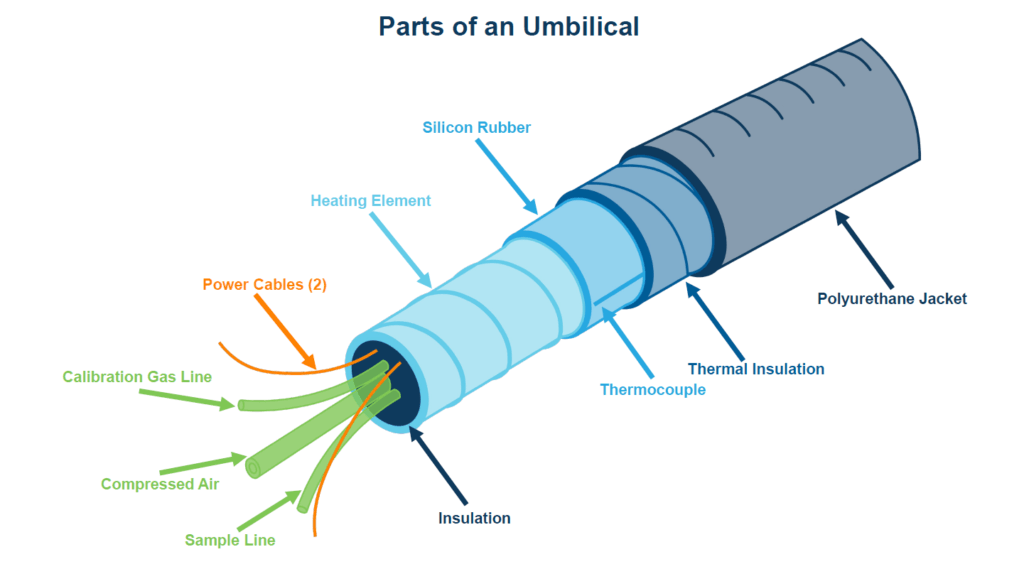

Continuous Emissions Monitoring 101: Extractive CEMS Umbilical

Read this article to learn more about extractive CEMS umbilicals, from construction and installation to maintenance best practices.

How to Successfully Plan and Complete a Relative Accuracy Test Audit

Learn about what a Relative Accuracy Test Audit (RATA) is and what measures to take leading up to your test, the day of, and afterwards.

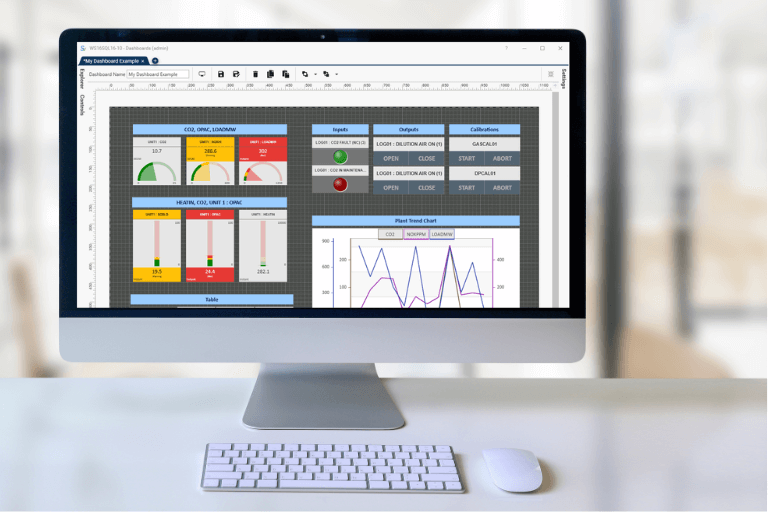

Challenge vs. Solution: Enhancing Emissions Data Review & Reporting with StackVision

Accurate air emissions data is critical for regulatory compliance–even small discrepancies can lead to reporting issues, audits, and penalties. While daily and weekly data reviews are not required by regulations, […]

Minimizing CEMS Downtime: Maintenance & Upgrade Strategies

CEMS downtime can lead to compliance risks and operational inefficiencies. This guide covers essential strategies for maintaining hardware, upgrading systems, and managing spare parts to minimize disruptions. Field Service Technician V and SME John Cutaia shares how to keep your Continuous Emissions Monitoring System (CEMS) operating efficiently with proactive maintenance and timely upgrades.

Why It Pays to Upgrade Your Data Acquisition System

Upgrading your Data Acquisition System (DAS) isn’t just about staying current—it’s about improving efficiency, ensuring compliance, and reducing costs. Whether you’re facing outdated technology, new regulations, or inefficiencies, the right DAS can streamline operations and enhance data visibility. Learn the key signs that it’s time for an upgrade and how a modern system can maximize your ROI.

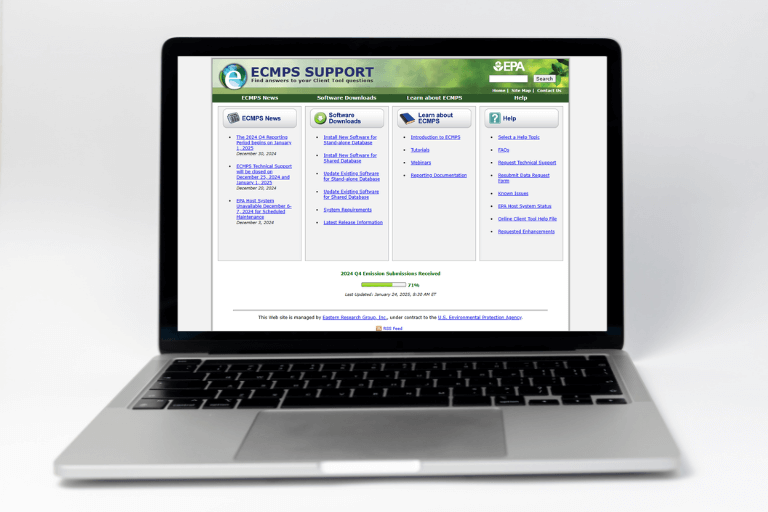

ECMPS 2.0 Update: Key Information You Need to Know

Learn about the latest ECMPS 2.0 updates from the EPA, key changes, and how ESC Spectrum is helping you stay prepared.

Understanding Part 60 and Part 63 Excess Emissions and Performance Summary Reports

This blog dives into Part 60 and Part 63 reporting requirements, specifically focusing on Semiannual Excess Emissions and Monitoring Systems Performance Reports.

Tracking Fuel Gas Sulfur Content: Why It Matters and How to Do It Right

Accurate fuel gas sulfur tracking is critical in the oil and gas industry to meet regulatory standards, protect equipment, and reduce environmental impact. This blog explores challenges in monitoring sulfur content, methods like Continuous Emissions Monitoring Systems (CEMS), and how advancements in technology help industries achieve precise and reliable sulfur management.

Understanding the Data Assessment Report (DAR) for CEMS Audits

The Data Assessment Report (DAR) is a crucial but often overlooked component of CEMS audit compliance. This guide breaks down what needs to be included, from quarterly accuracy results to EPA audit sample requirements, helping you keep up with regulations and streamline your reporting process.

Tail Gas Treatment Units (TGTUs): Essential for Sulfur Recovery

Read this post to discover how Tail Gas Treatment Units (TGTUs) help refineries meet stringent sulfur recovery and emissions control standards. This blog covers essential TGTU technologies, regulatory requirements, and the vital role that TGTUs play to improve sulfur recovery efficiency.

PM CEMS and PS-11 Compliance Explained: Best Practices for Reliable Particulate Matter Monitoring

Read this post for a deeper understanding of the certification requirements for PM CEMS, with a special emphasis on the PS-11 Correlation.

The Importance of Staged Flares and Valve Positioning in Refining Processes

This blog explores the critical role of staged flares and valve positioning in refining operations, highlighting their impact on emissions monitoring, compliance with EPA regulations, and overall operational efficiency through the use of StackVision DAS.

Understanding Thermal Oxidizers and Their Role in Emission Control: Key Insights for the Refining Industry

Learn how thermal oxidizers operate alongside data acquisition systems to ensure EPA compliance and accurate data collection in refineries.

Benefits of Upgrading Your Data Acquisition System (DAS)

In today’s regulatory landscape, ensuring air emissions compliance is crucial. A reliable and robust Data Acquisition System (DAS) plays a pivotal role a Continuous Emissions Monitoring Systems (CEMS). Upgrading your DAS offers numerous benefits, read more to explore the advantages of upgrading and what you can expect from the DAS changeout process.

Enhance Sulfur Recovery Unit (SRU) Data Collection and Reporting 101

Learn how integrating our Data Acquisition System, StackVision, improves Sulfur Recovery Unit (SRU) emissions monitoring, ensuring EPA compliance and easing difficulties with data collection in refineries.

Monitoring Flare Gas Flows: Challenges and Solutions

This blog post examines the challenges and solutions of monitoring flare gas flows within industries like oil and gas, chemical processing, petrochemical, and refining. Explore how advanced technologies along with innovative monitoring systems, ensure accurate measurements, regulatory compliance, and operational efficiency.

Adapting to New EPA Ethylene Oxide Regulations: The Role of CEMS

This blog post examines a series of 2024 EPA Regulations on Ethylene Oxide and explores how Continuous Emission Monitoring Systems (CEMS) can help facilities navigate these new standards.

NSPS OOOOb & OOOOc Rules on Methane: What You Need to Know

Discover key insights on the EPA’s finalized NSPS OOOOb and OOOOc rules targeting methane emissions in the oil and natural gas sector. Learn about the stringent measures, compliance requirements, and industry impacts of these essential regulations effective November 2022.

Particulate Matter CEMS: Navigating New EPA Regulations

This article will walk you through the role of Particulate Matter (PM) Continuous Emissions Monitoring System’s (CEMS) in air compliance.

Refining Processes: Understanding Flare Requirements in EMACT

The Ethylene Manufacturing National Emission Standards for Hazardous Air Pollutants (NESHAP) under Subpart XX and YY establish requirements to control hazardous air pollutants (HAP) emissions from ethylene production units. This blog post focuses on the flare requirements specified in these regulations.

Gas Chromatography CEMS for Refining: Performance Specification 9

Learn more about 40 CFR Part 63 Subpart CC Performance Specification 9 to ensure accurate measurement of gaseous organic compound emissions. Performance Specification 9 (PS-9) establishes the requirements and procedures for Gas Chromatographic Continuous Emission Monitoring Systems (CEMS) in stationary sources.

Navigating Refining Regulations: 40 CFR Part 63 Subpart CC

Learn more about National Emission Standards for Hazardous Air Pollutants from Petroleum Refineries specifically on 40 CFR Part 63 Subpart CC. This blog post outlines the steps to comply with Subpart CC and how ESC Spectrum can equip your facility to streamline emission monitoring needs.

Retiring a CEMS: Ensuring a Smooth and Secure Process for Your Facility

Retiring a unit can be a long-winded and stressful process. This blog post gives some insight into how to make the process go smoothly.

Understanding Air Emissions Regulations for Industrial Cooling Towers & Heat Exchangers

Explore industrial process cooling towers and heat exchangers and their requirements under NSR in Texas and nationwide.

Upgrading Your CEMS in Refineries and Petrochemical Facilities

This blog post will explore the various upgrade options for CEMS in refining and petrochemical facilities, detailing the benefits of each.

Final Rules – MATS Residual Risk & Technology Review and Greenhouse Gas (GHG) Performance Standards

In May of 2024, the EPA finalized stricter rules for Mercury Air Toxic Standards (MATS) and Greenhouse Gas (GHG) Performance Standards. Key changes include tighter limits on particulate matter and mercury emissions, mandatory use of PM Continuous Emissions Monitoring Systems (CEMS), and new compliance timelines. Learn more about how these final rules can affect your facility.

Data Acquisition in Refineries: Plant Process Systems vs Data Controllers

This blog post will walk you through all the ways using the 8864 Data Controller in refineries can mitigate risks for your facility.

Electronic Data Report (EDR): A Guide to Effective Emissions Data Management

Dive into the world of Electronic Data Reports (EDRs) with our expert guide. Learn how to manage emissions data effectively, ensure compliance, and avoid errors. Explore practical tips and real-world solutions from industry experts.

Best Practices for Replacing Your Analyzers Under Part 75

This article explores the significance of stack analyzer replacement due to factors like aging, obsolescence, and poor performance. Gain valuable insights into the complexities of CEMS analyzer replacement and recertification, aiming to assist industrial and utility plants in maintaining compliance with air quality regulation 40 CFR Part 75.

Are Your CEMS Analyzers Obsolete?

This article will help you identify if your CEMS analyzers are obsolete, what this means for your facility, and how ESC Spectrum can help!

5 Tips to Help Maintain Your CEM Systems

This article explores CEM System maintenance tips to ensure compliance with EPA regulations including Calibration, Linearity Checks, Data Validation and more.

Decoding the World of Flare Gas Monitoring

This article explores the details of flaring, including types of flares, operations, applications, and monitoring methods.

Advantages of Outsourcing Reporting for Air Emissions Compliance

This article discusses the crucial role of outsourcing reporting in streamlining air emissions compliance for industrial operations. It highlights the complex regulatory landscape governed by regulations such as 40 CFR Part 60, Part 63, and Part 75. With the expertise of ESC Spectrum’s reporting team, facilities can ensure timely, efficient, and customized compliance solutions, mitigating risks, and maintaining data integrity while navigating regulatory changes seamlessly.

Best Practices for QA Test Management in Petrochemical Facilities

Learn how Petrochemical facilities’ can best utilize QAInsight software to ensure safety and compliance for their business.

EPA “Good Neighbor” Plan – The Saga Continues

Learn about the latest updates to the EPA’s Good Neighbor Plan, including a proposed supplement that would cover 5 states.

2023 Regulatory Snapshot: Key Changes Unveiled

Dive into the 2023 key regulatory updates for ECMPS 2.0, MATS Residual Risk and Technology Review, Low Mass Emissions (LME), and more. Stay ahead of the curve as we guide you through each topic and equip you with the tools to navigate 2024.

Understanding New In-Situ Optical Monitoring Technology – What is it and is it Right for Your Facility?

Read about recent advancements, particularly demonstrated by EPRI on gas turbine combined cycle and coal stacks, that have sparked a growing interest in the integration of in-situ optical monitors in a CEM framework.

Improving Operational Efficiency with Data Acquisition Systems in Refineries

This blog post will walk you through all the ways having a data acquisition system for refineries can improve overall operations and efficiency.

Mastering Air Compliance: Best Practices for Your Data Acquisition System

In the intricate landscape of environmental regulations, industries face the ongoing challenge of remaining compliant. Read this blog post for a comprehensive guide on how to navigate the complexities of these regulations with confidence, starting with your Data Acquisition System.