What is an Extractive CEMS Umbilical?

The CEMS Umbilical is a bundle of pneumatic tubes and electrical wires used to interconnect the probe, the gas analyzers, and the gas transport system. The typical umbilical requires 220VAC power.

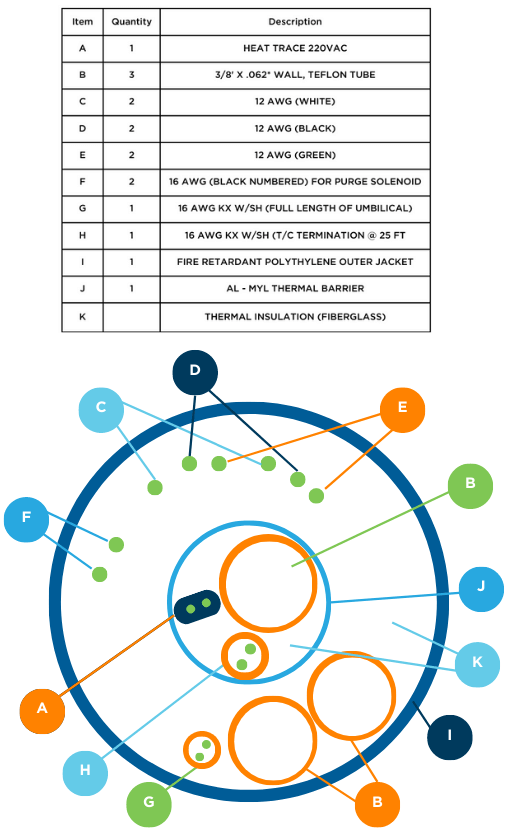

Construction of the Extractive CEMS Umbilical

Wiring

The umbilical system includes the control wiring for the stack J-box and the AC voltage for the pride and umbilical heaters (typically 115V and 24V, respectively).

Tubing

Typically, the umbilical only has the tubes listed below, but it is possible to add a spare tube. If more than one spare is desired, it may become difficult to keep the entire umbilical rated above 80°F.

- One 3/8′ PFA Teflon tube for transportation of calibration gas to the probe.

- One 3/8′ Teflon tube for transportation sample CEMS.

- One 3/8′ PFA Teflon for transporting instruments and purging air to the probe.

Insulation/Jacket

The tube/wire bundle is wrapped in an aluminized Mylar thermal barrier. It is surrounded by Aspen Aerogel which has four times better-insulating properties than fiberglass and allows the umbilical to be smaller in overall diameter.

Heater

Two Type “K” thermocouple wires are provided for measuring the temperature of the umbilical and probe heater. The typical heater consumes 18 watts/foot.

Heater nodes run the length of the umbilical every three inches. Temperatures are normally set between 250° and 350°. The temperature is controlled by a controller usually mounted in the CEMS cabinet.

Installation

There are three considerations with the installation of an umbilical:

- Securing the umbilical

- The proper length of the umbilical

- The problems that may arise and how to prevent them

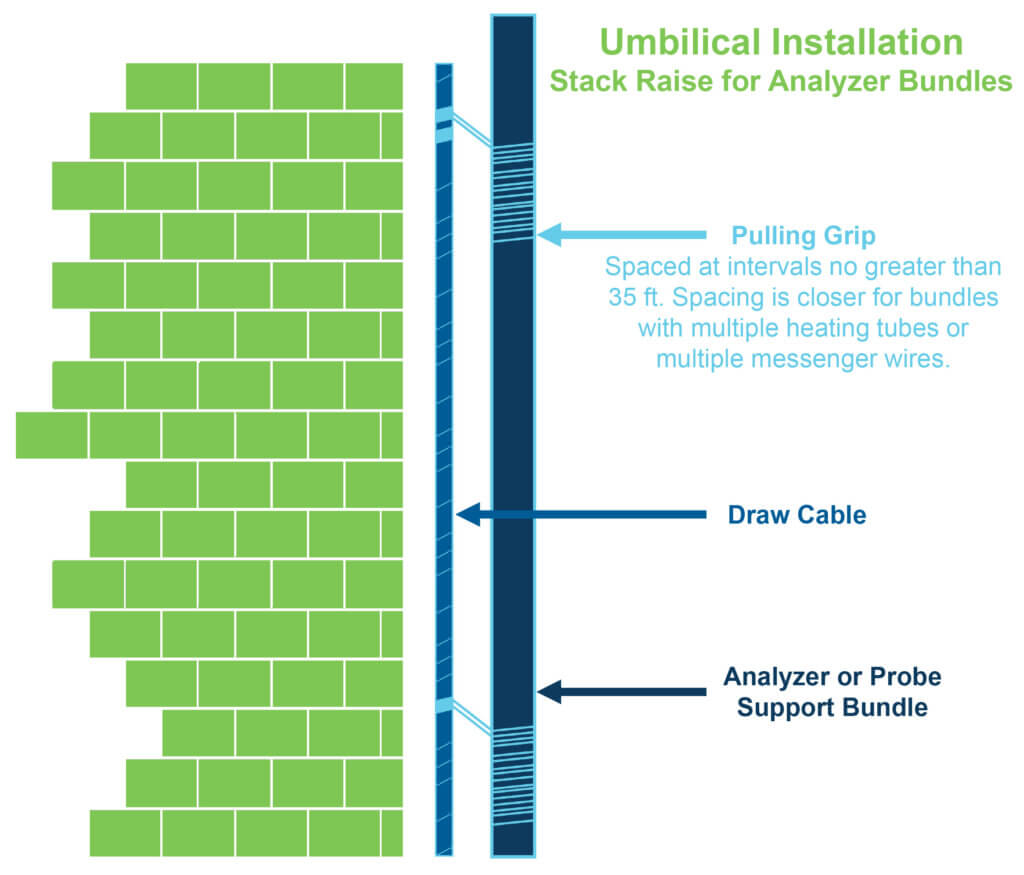

Securing the Umbilical

Enough slack must be left at each end to connect the umbilical.

The umbilical must be supported every 10 feet on vertical and five feet on horizontal runs. Kellum grips are the typical way of installing the umbilical to the stack; however, other methods, such as running the umbilical in conduit, have been used. Kellum Grips work like a Chinese finger trap where increased tension creates a tighter grip.

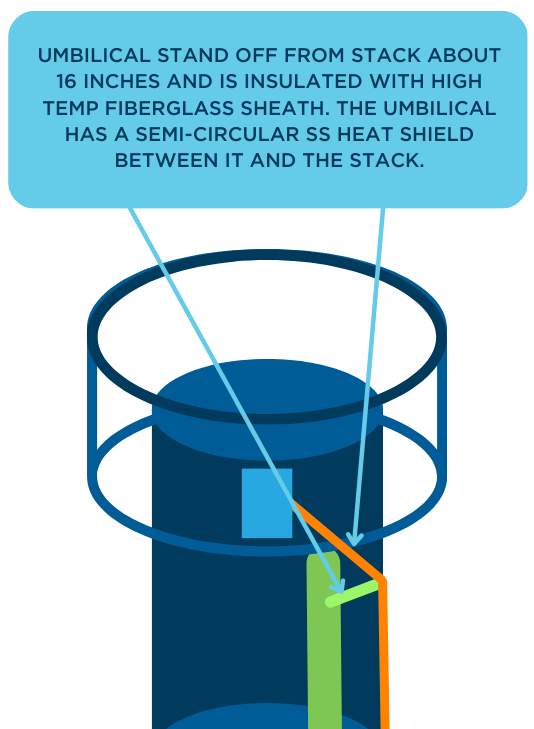

The Kellum Grips coiled wrap around the umbilical is secured to the stack using a draw cable to provide spacing between the umbilical and the stack. This prevents the high temperatures of the stack from coming into contact with the umbilical.

Length

Each application determines the length of the umbilical. The minimum that can be produced is 100′ runs. Approximately 10′ extra is required at each end for installation.

The umbilical needs to be one continuous length. This means that two pieces cannot be spliced together to make a run longer.

Because the umbilical heater will draw too much power for the 14 gauge wire used, a second power source is needed if the umbilical reaches lengths greater than 250′.

Two heater wires with separate power sources are used for longer-length umbilicals.

Since the heater nodes are every 3′, when terminating the umbilical, the installer must be careful to have the node as close to the stripped ends as possible. Any sample line that is not heated has the potential for condensation.

There is a designated stack end and a CEMS cabinet end. These ends wile marked and must be installed in the correct orientation.

Potential Issues

Certain problems can arise if preventative action is not taken.

- The umbilical must always have a downward slope. If a “drip-loop” is formed, moisture can accumulate, and the sample line could get clogged.

- The umbilical cannot be exposed to conductive or convective heat above 130°F. Excessive temperatures will melt the outside sheathing.

- The PFA Teflon tube can outgas CO, which can affect CEMS readings when monitoring THC and low levels of CO (less than 5ppm). Some things done to deal with this out-gassing include using stainless steel tubes instead of the Teflon tubes and purging the system with clean air to “burn” out the CO at start-up (typically done at 350°F for 24-48 hours).

- A minimum 30″ bend radius needs to be observed so as not to pinch the sample line.

Maintenance

While there is usually no maintenance on an umbilical, some applications might require periodic cleaning. Acetone can be flushed through a sample tube to clean out any residue that forms and collects. In these cases, an additional tube can be convenient so as not to disrupt monitoring.

How Can ESC Spectrum Help?

Interested in learning a more comprehensive overview of how CEM Systems work? Read Understanding Continuous Emissions Monitoring Systems (CEMS): A Comprehensive Guide. This guide will give you a complete understanding of all the components in the flow of a CEMS.