This case study will focus on how ESC Spectrum helped solve Lightstone Energy’s Lawrenceburg and Darby Generating Station challenges with a full suite of ESC Spectrum products and services, including:

- StackVision DAS Software

- Reporting Services

- Engineering Services

- Analyzer Upgrade Services

- CEMS Maintenance Services

Jeffrey Darling, the Environmental Health & Safety Manager for both facilities, explains how ESC Spectrum empowered him to meet environmental compliance requirements, keep his facilities running efficiently, maintain CEMS equipment, and save close to $400,000.

Darby and Lawrenceburg Generating Stations Overview

Lightstone Generation, a joint venture between private equity firms Blackstone and ArcLight Capital Partners, acquired Lawrenceburg and Darby Generating Stations from American Electric Power (AEP) in 2017. The Lawrenceburg Generating Station is a 1,232-megawatt natural gas power station located in Lawrenceburg, IN. The Darby Generating Station is a 480-megawatt natural gas power station situated in Darby Township near Mount Sterling, Ohio.

Generating Stations Challenges

As the Health & Safety Manager, Jeffery Darling manages all the environmental responsibilities for the Lawrenceburg and Darby Generating Stations. Communicating and implementing environmental requirements facility-wide is a time-consuming challenge, and meeting the data collection and management requirements defined by the Refinery Sector Rule (RSR) leaves no room for error. In addition, the lack of environmental staff support can add extra work to others employed at these facilities.

“You sit down for Thanksgiving or Christmas dinner, and the alarm goes off, and you’re gone for an hour or maybe even five hours,” explained Darling.

To address environmental challenges and a lack of staff, Darling turned to ESC Spectrum for help.

StackVision and 8864 Data Controller Implementation

The switch to ESC Spectrum’s StackVision DAS (using the 8864 Data Controller) was a “no-brainer,” according to Darling. The ease of reporting, cylinder management capabilities, and intuitive navigation of the Windows-based software made it the best choice for compliance and monitoring at Darby and Lawrenceburg facilities.

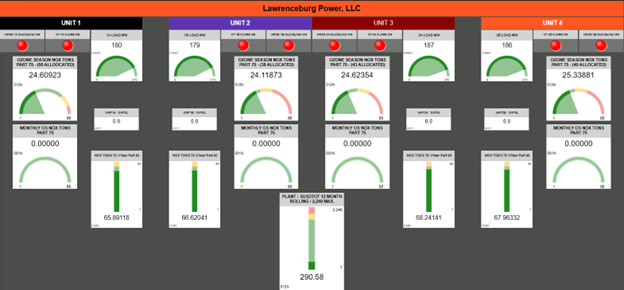

StackVison’s features offered Darling and his team more flexibility with dashboards and efficient Environmental Protection Agency (EPA) reporting. ESC Spectrum was able to customize 25 different dashboards (all in use during the quarter) for the Lawrenceburg facility so that they could switch back and forth from one to another as needed.

After the success at Lawrenceburg in 2018, Darling worked with ESC Spectrum to upgrade Darby Generating Station’s Teledyne DAS to StackVision (using the 8864 Data Controller) while undergoing an analyzer upgrade. The change went smoothly and quickly.

"We transitioned into StackVision and 8864s, and at the same time, put in a new server, and it all happened in one day."

Jeffrey Darling, Lightstone Energy, LLC

Good Data Results in Cost Savings

After implementation, the data at the Lawrenceburg facility indicated a 22.5-ton discrepancy between the old Teledyne DAS and the new StackVision data. By discovering this error, at $3,000/ton, this equated to a cost savings of $65,700.

Regarding their Low Mass Emitting (LME) unit under the previous vendor’s DAS, the Darby facility only had two emission factors: uncontrolled and controlled. The units ran base uncontrolled and base peak any time they were online. With StackVision, Darling was able to use three emissions factors – uncontrolled, base, and peak. By switching from peak-only to peak, base, and uncontrolled, the Darby station was able to save tons on NOx emissions, and they are currently operating at $8,000/ton.

With the help of ESC Spectrum, both facilities pulled all the data out for their Q3 and Q4 submissions and resubmitted it to ECMPS. The updated data indicated they overreported by over 39 tons. At $8,000/ton, this correction equated to cost savings of approximately $320k.

Unlocking Success Through Customizable Dashboards

Both facilities needed an Ozone Season NOx dashboard to calculate critical information. When he found out they needed to comply with the new Cross-State Air Pollution Rule (CSAPR) regarding daily tons of NOx emitting in ozone season only, Darling requested the ability to track that total value on a dashboard in real-time. The ozone dashboard proved especially helpful because he can now use building and predictive totals to ensure his facilities stay within their credit limits.

"I can't say enough about [ESC Spectrum's] Reporting Services and the job they do. They keep our facilities on track: that's the biggest thing."

Jeffrey Darling, Lightstone Energy, LLC

Experts in CEMS Maintenance Services & Analyzer Replacement

Previously, the generating stations used Control Analytics, Inc. for their CEMS maintenance. ESC Spectrum acquired Control Analytics in December 2021. When Darby and Lawrenceburg installed new analyzers in 2021, they turned to ESC Spectrum for installation and annual maintenance.

“The people I have worked with from Control Analytics, now part of ESC Spectrum, are top-notch,” explained Darling.

Darling utilized ESC Spectrum’s CEMS maintenance services to provide onsite, expert technicians to:

- Review calibrations, alarms, and trends to identify system deficiencies

- Perform recommended analyzer, sample conditioning system, and probe maintenance

- Combined quarterly testing on each unit, with a written report detailing all work performed

- Including unlimited 24/7 phone support and priority emergency response services

- Engineering service hours for StackVision configuration needs.

ESC Spectrum replaced the Teledyne (TML) analyzers for NOX, O2, and CO analyzers at Lawrenceburg, as well as a spare set for emergency use. Installation, ancillary equipment, extended warranty, and maintenance visits are included, so Darling knows the analyzers are well-maintained at all times.

One-Stop-Shop for CEMS & DAS Needs

By using various products and services from ESC Spectrum, Darling has been able to meet his compliance and regulatory challenges at the Darby and Lawrenceburg Generating Stations, as well as save Lightstone money. As a result, both facilities operate at their most efficient capacities.

Need help keeping your facilities running smoothly? Contact us today to see how we can help.