CEMDAS™ Evolution

COMDAS™ Evolution

Data Acquisition Systems

CEMDAS & COMDAS are user-friendly systems

that operate with a Programmable Logic Controller (PLC)

and are ideal for

Ethanol and Biomass facilities

to monitor and report air emissions data.

See critical data at-a-glance with a user-configurable dashboard

The CEMDAS (for Continuous Emissions Monitoring) and COMDAS (for Continuous Opacity Monitoring) dashboards are user-configurable, ensuring that after login, you see everything you need to know instantly.

Users can configure:

- Displayed data

- Appearance of the data in chart, graph or gauge format

- Placement of data on the dashboard

- Table layout

CEMDAS & COMDAS provides powerful reporting tools for monitoring and compliance

CEMDAS Evolution comes with pre‐configured reports guaranteed to meet the EPA’s Part 60, Part 75, Part 266, and Part 503 requirements. COMDAS Evolution comes with pre‐configured reports guaranteed to meet EPA’s Part 60 requirements, and all special State requirements (i.e. Pennsylvania Department of Environmental Protection, Michigan Department of Environment, Great Lakes and Energy, and more).

Reports can be generated automatically or manually and saved to a wide variety of formats including .pdf, .mht, .rtf, .xls, .xlsx, .csv, .text, and image files (.bmp, .gif, .jpeg, .png, .tiff, .emf, and .wmf).

CEMDAS and COMDAS provide the flexibility to report with customizable parameters, timeframes, and output formats.

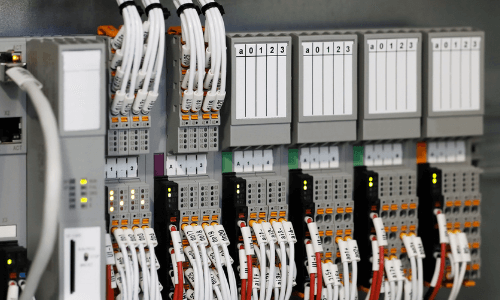

Operate with a PLC-based CEMCON System Controller

CEMDAS and COMDAS Evolution utilize a CEMCON PLC Controller System. In most applications, an Allen Bradley Compact Logix PLC is utilized to interface between the CEMS hardware and the CEMDAS and COMDAS PC.

CEMCON offers flexible I/O and communication with a plant’s DCS or SCADA via analog, digital, or Ethernet I/P communication.

CEMDAS and COMDAS are supported by an in-house, US-based 24/7/365 customer support team.

These data acquisition systems are backed by best-in-class customer support from a dedicated team of experts and is supported by online and in-person training.

Our DAS services teams are standing by to support additional needs and include:

CEMDAS and COMDAS Evolution Features

- On-the-fly alarm editing

- Email alarm notifications

- Pre-configured or customizable reports for state and local regulations

- Email reports

- Generate automatically or manually

- System Flags

- Alarms

- Emissions States

- Process Codes

- Bias and Historical Values

- Cal Setup

- Cal Timing

- System Constants

- Alarms

- User Permissions and Accounts

- Automatic backups

- Configurable User Permissions and Accounts

Michael is always very professional and knowledgeable.

I am always confident things will be resolved quickly with him.

Dave Patterson

Consulting Engineer (Air Quality Group), Ameren

ESC Spectrum has provided excellent engineering and procurement support.

Juan Cantu

Analyzer Specialist, ENglobal

Alex was very helpful in resolving the issues that I brought to him.

Kevin Bugay

Process Engineer, Cardinal Corporation

Even though we are only data logger users, the support staff has always been extremely nice,

very timely and completely knowledgeable on the topic at hand.

John Markely

Sr. Environmental Engineer, Kyger Creek

Very helpful, understood my issue and found the fix I needed.

Dane Ruberg

Instrument Technician, Xcel Energy

Scott is fantastic, very knowledgeable and very helpful!

Always know I am going to get the help I need when he answers the phone.

Celena Arreola

Environmental Engineer, El Paso Electric

Outstanding customer service!!!

Rick Gregory

IT Specialist/Network Admin, Calumet Specialty Partners

The customer service provided was quick and the agent sent additional information.

Ann Woods

Environmental Scientist, Agua Fria Generating Station

Excellent work!

Daniel Fefer

Contractor, Exelon

Case Studies

StackVision™ Case Study: New Orleans Power Station

Learn how the New Orleans Power Station used StackVision for Reciprocal Internal Combustion Engine (RICE)-specific monitoring and reporting.

StackVision™ Case Study: Petrochemical Plant

Learn how a Petrochemical plant used the StackVision Data Acquisition System for a +200K ROI by reducing Emergency Work Orders by 50%.

CEMS Solutions Case Study: O-I

Learn how the Owens-Illinois (O-I) glass manufacturer used ESC Spectrum’s full suite of CEMS solutions to meet air compliance challenges.