According to the Environmental Protection Agency, “CEM system sample probes used in fully extractive systems usually incorporate an external filter, internal filter, or both, to prevent particulate matter from entering the sample line. Most systems incorporate a “blowback” cleaning cycle, where high-pressure air is periodically blown back through the filter to remove accumulated materials. In some cases, this procedure may not be effective, especially if particulate matter is sticky or if a particulate cake builds up rapidly due to a process upset.”

The Role of CEM Filters

Our team of experienced Field Service Technicians regularly check CEM equipment filters during their service visits. It may seem minor, but CEM filters play an integral role in the successful operation of your entire system. They need to be inspected regularly as part of routine maintenance. This inspection often complies with your Quality Assurance and Quality Control (QAQC) plan.

Filters keep systems clear of contaminants that may affect equipment performance. NOx and SO2 analyzers have filters on the fans found in the back of units. While monthly inspection and cleaning are recommended, they often should be increased or decreased with dirtier or cleaner surroundings. Filters should be checked at least once every six months.

Reasons Why It’s Important to Inspect Your CEM Filters

It Will Help Your Equipment Live Longer

A clean filter allows sample gases to pass through the system without obstructions, preventing further repairs that a clogged filter might cause.

It Keeps Your System Clean

The measurements and data collected by your system for operations and/or compliance depend on the efficient operation of your analyzers, which a bad or dirty filter could compromise. A compromised analyzer means extra repairs, parts, and services you weren't anticipating.

It Will Keep Your Expenses Down

Failed calibrations, invalid data, or unstable reading from the analyzer that cannot be trusted mean more troubleshooting for your CEMS Technicians and even impacts your compliance or reporting department. More work, more repairs, and more expenses can impact operational decisions.

Next Steps: Check Your Filters!

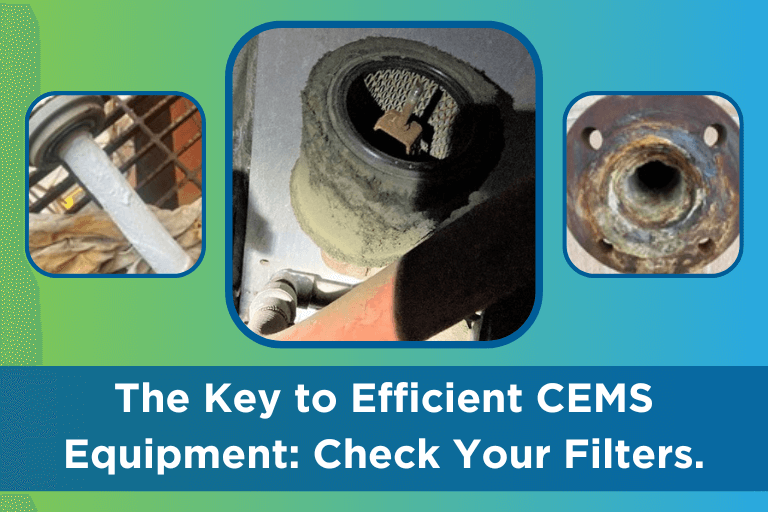

Take a look at your filters; if they look like a grey cat, it’s time for maintenance! If you have questions about filters or need assistance with your maintenance, contact us, and we’ll make sure your monitoring systems are functioning properly. Considering a new CEMS filter? We supply various CEMS Equipment Filters from a wide range of manufacturers.

Interested in learning a more comprehensive overview of how CEM Systems work? Read Understanding Continuous Emissions Monitoring Systems (CEMS): A Comprehensive Guide. This guide will give you a complete understanding of all the components in the flow of a CEMS.