CEMS Probe Maintenance: Extractive vs. Dilution Systems

CEMS probes are the first point of contact with the gas sample line in your emissions monitoring system. Discover why routine maintenance is critical—and how to do it right.

Where to Install CEMS Probes, Flow Sensors & Opacity Monitors (According to EPA Guidelines)

In this article, read about where you can locate your plant’s CEMS Probes, Flow Probes & Opacity Units on your stack unit & what EPA regulations apply to them.

CEMS Filter Maintenance Tips for Reliable Performance

Regular CEMS filter maintenance is one of the easiest, and most effective, ways to ensure accurate emissions data and keep your system running smoothly. This article covers why filter care matters, and best practices to keep your system running smoothly year-round.

CEMS Fails From the Field: What Went Wrong & How to Fix It

Discover the top causes of CEM system failures and how to prevent them. Get expert troubleshooting advice and maintenance strategies to reduce downtime.

Continuous Emissions Monitoring 101: Calibration Gas & Requirements

This article will discuss and clarify calibration gas requirements for CEMS users including, system calibration, cal gas bottles, and more.

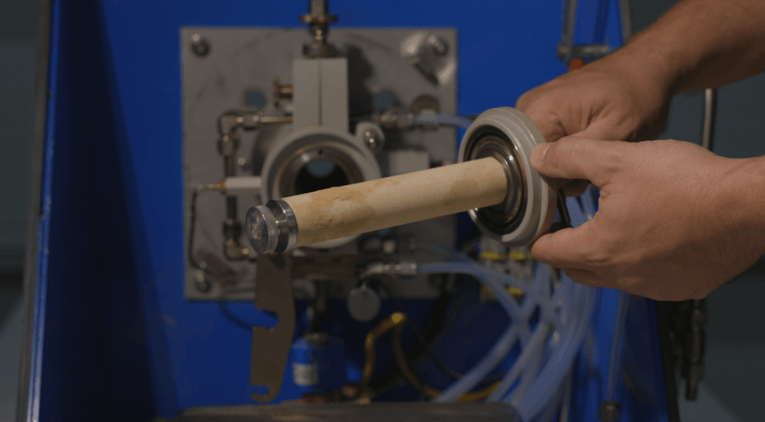

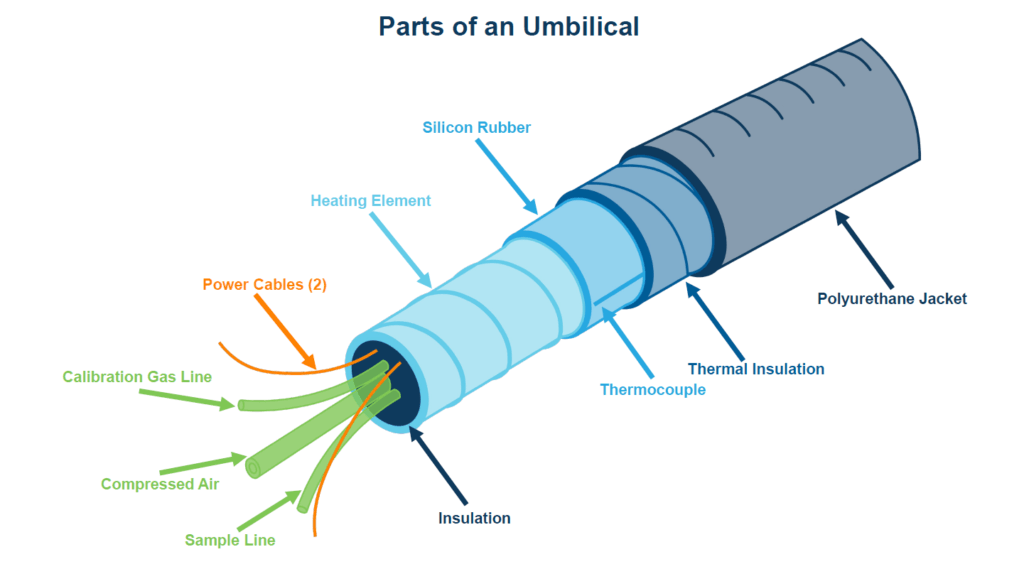

Continuous Emissions Monitoring 101: Extractive CEMS Umbilical

Read this article to learn more about extractive CEMS umbilicals, from construction and installation to maintenance best practices.

U.S. Environmental Protection Agency (EPA) Greenlights ESC Spectrum’s New Integrated Path CEMS (IP CEMS) Technology for Air Emissions Compliance

ESC Spectrum, a leading provider of environmental compliance solutions, is excited to announce the successful demonstration of Integrated Path CEMS for air emissions monitoring and reporting.

Minimizing CEMS Downtime: Maintenance & Upgrade Strategies

CEMS downtime can lead to compliance risks and operational inefficiencies. This guide covers essential strategies for maintaining hardware, upgrading systems, and managing spare parts to minimize disruptions. Field Service Technician V and SME John Cutaia shares how to keep your Continuous Emissions Monitoring System (CEMS) operating efficiently with proactive maintenance and timely upgrades.

Understanding Part 60 and Part 63 Excess Emissions and Performance Summary Reports

This blog dives into Part 60 and Part 63 reporting requirements, specifically focusing on Semiannual Excess Emissions and Monitoring Systems Performance Reports.

Tracking Fuel Gas Sulfur Content: Why It Matters and How to Do It Right

Accurate fuel gas sulfur tracking is critical in the oil and gas industry to meet regulatory standards, protect equipment, and reduce environmental impact. This blog explores challenges in monitoring sulfur content, methods like Continuous Emissions Monitoring Systems (CEMS), and how advancements in technology help industries achieve precise and reliable sulfur management.

Understanding the Data Assessment Report (DAR) for CEMS Audits

The Data Assessment Report (DAR) is a crucial but often overlooked component of CEMS audit compliance. This guide breaks down what needs to be included, from quarterly accuracy results to EPA audit sample requirements, helping you keep up with regulations and streamline your reporting process.

Tail Gas Treatment Units (TGTUs): Essential for Sulfur Recovery

Read this post to discover how Tail Gas Treatment Units (TGTUs) help refineries meet stringent sulfur recovery and emissions control standards. This blog covers essential TGTU technologies, regulatory requirements, and the vital role that TGTUs play to improve sulfur recovery efficiency.

PM CEMS and PS-11 Compliance Explained: Best Practices for Reliable Particulate Matter Monitoring

Read this post for a deeper understanding of the certification requirements for PM CEMS, with a special emphasis on the PS-11 Correlation.

New Release: Prism Version 2.0 Data Acquisition System

We’re excited to announce the release of Prism Version 2.0! This release provides new features designed to make CEMS compliance and monitoring easier and more productive than ever.

Monitoring Flare Gas Flows: Challenges and Solutions

This blog post examines the challenges and solutions of monitoring flare gas flows within industries like oil and gas, chemical processing, petrochemical, and refining. Explore how advanced technologies along with innovative monitoring systems, ensure accurate measurements, regulatory compliance, and operational efficiency.

Adapting to New EPA Ethylene Oxide Regulations: The Role of CEMS

This blog post examines a series of 2024 EPA Regulations on Ethylene Oxide and explores how Continuous Emission Monitoring Systems (CEMS) can help facilities navigate these new standards.

Particulate Matter CEMS: Navigating New EPA Regulations

This article will walk you through the role of Particulate Matter (PM) Continuous Emissions Monitoring System’s (CEMS) in air compliance.

Retiring a CEMS: Ensuring a Smooth and Secure Process for Your Facility

Retiring a unit can be a long-winded and stressful process. This blog post gives some insight into how to make the process go smoothly.

Upgrading Your CEMS in Refineries and Petrochemical Facilities

This blog post will explore the various upgrade options for CEMS in refining and petrochemical facilities, detailing the benefits of each.

Are Your CEMS Analyzers Obsolete?

This article will help you identify if your CEMS analyzers are obsolete, what this means for your facility, and how ESC Spectrum can help!

New Release: RATAView™ Version 1.5 Now Available

RATAView Version 1.5 release offers new features and enhancements to help stack testers’ perform RATA tests accurately and efficiently.

New Release: Prism Version 1.9 Data Acquisition System

We’re excited to announce the release of Prism Version 1.9! This release provides new features designed to make CEMS compliance and monitoring easier and more productive than ever.

ESC Spectrum Academy Introduces New Online, Self-paced Continuous Emissions Monitoring System Training Module

ESC Spectrum’s new CEMS Training features 16 Courses free for customers with active DASProtect Fortress maintenance contracts.

Continuous Emissions Monitoring 101: Oxygen & Flow Analyzers

Read this article to learn more about two of the most reliable analyzers in the CEMS world: oxygen and flow.

Continuous Emissions Monitoring 101: CO Analyzers

Read this article to learn more about CEMS Analyzers, specifically NDIR technology used to measure Carbon Monoxide (CO).

New Release: Prism Version 1.8 Data Acquisition System

We’re excited to announce the release of Prism Version 1.8! This release provides new features designed to make CEMS compliance and monitoring easier and more productive than ever.

New Release: RATAView™ Version 1.4 Now Available

RATAView Version 1.4 release offers new features and enhancements to help stack testers’ perform RATA tests accurately and efficiently.

Continuous Emissions Monitoring 101: SO2 Analyzers

Read this article to learn more about Pulsed Fluorescence technology in CEMS analyzers used for measuring Sulfur Dioxide (SO2) gas.

Continuous Emissions Monitoring 101: NOx Analyzers

Read this article to learn more about NOx Analyzers, how they measure NOx through Chemiluminescence, and how to maintain your NOx analyzer.

Continuous Emissions Monitoring 101: Air Clean Up Systems

Read this article to learn more about CEMS Air Clean-Up Systems in the CEMS cabinet or shelter, such as preventative maintenance & components.

Continuous Emissions Monitoring 101: Sample Conditioning Systems

Read this article to learn more about CEMS sample conditioning systems, located in the CEMS cabinet or shelter.

Continuous Emissions Monitoring 101: Extractive CEMS Probes

Read this article to learn more about extractive CEMS Probe processes, steps, and components from industry experts.

New Release: RATAView™ Version 1.3 Now Available

RATAView Version 1.3 release offers new features and enhancements to help stack testers’ perform RATA tests accurately and efficiently.

New Release: Prism Version 1.7 Data Acquisition System

We’re excited to announce the release of Prism Version 1.7! This release provides new features designed to make CEMS compliance and monitoring easier and more productive than ever.

Portable CEMS: The Search for Accuracy

In this article, we will cover the key takeaways when shopping for a portable gas analyzer (portable CEMS) to measure emissions.

Continuous Emissions Monitoring 101: Extractive CEMS Flow Overview

Read this article to learn more about extractive CEMS flow processes, steps, and components from industry experts.

QAQC Manuals: What You Need to Know

In this article, we will outline requirements and discuss the elements a good QAQC Manual typically includes.

Resubmitting Data to ECMPS

While resubmitting data can seem intimidating, it does happen from time to time. This article covers helpful tips for such a process.

Continuous Emission Monitoring System: Upgrade or Replace?

Are you upgrading or replacing a Continuous Emission Monitoring System? Read more to learn which one is right for your facility so your CEM System is up to date with the latest technology.

Keep Your QAQC Plans Up-to-Date to Keep Your Facility Safe (and Audit-Ready)

Learn more about why it is important to keep your facility’s QAQC plan up-to-date, both for facility safety and audit preparedness.

New Release: RATAView™ Version 1.2 Now Available

RATAView Version 1.2 release offers new features and enhancements to help stack testers’ perform RATA tests accurately and efficiently.

New Release: Prism Version 1.6 Data Acquisition System

The Prism data acquisition system (DAS) Version 1.6 release provides new features designed to make CEMS compliance and monitoring easier and more productive than ever.

Increasing Demand for Ethanol Affects Your Monitoring Systems

Read about how the increasing demand for ethanol can affect your continuous emissions monitoring system components at your ethanol facility.

Update on 40 CFR 63 Subpart YYYY – Formaldehyde Emission Standards

This blog post discusses updates on 40 CFR 63 Subpart YYYY including changes, who is subject to YYYY, facility limits and more. Compliance with changes is required within 180 days of March 9, 2022 (i.e., September 6, 2022).

Webinar: Critical Compliance CEMS Administrative Tasks for Audits and Inspections

CEMS compliance relies on many things including various administrative tasks. In this session, Senior Regulatory Reporting Engineer, Susan Kennedy, will review administrative items that help demonstrate compliance of your system […]