Prism™

Data Acquisition System

Looking for a flexible, reliable CEMS Data Acquisition System?

Prism

is built on decades of experience in

air emissions compliance.

Prism allows you to easily capture, analyze, calculate, and report emissions data for federal, state and local environmental compliance.

Prism is a scalable DAS software solution that can operate in stand-alone and enterprise environments and ensures users meet regulatory reporting requirements for emissions. Prism operates on Microsoft’s Windows and SQL Server.

Prism works with the 8864 Data Controller to collect, monitor, QA, and report on emissions data from continuous monitoring systems accurately and reliably.

Facilities across the U.S. in a wide variety of industries rely on Prism for accurate and reliable air emissions monitoring and reporting to meet federal and state and local requirements.

Prism's user-friendly features help facilities create and submit reports with ease.

Prism was created by technicians for technicians to make CEMS compliance as easy and user-friendly as possible.

Reporting your continuous monitoring data and deviations is a critical obligation, but it doesn’t have to be frustrating. Prism has a number of features that make it easy for users to meet current and future regulatory reporting requirements.

Everything you need to know is at your fingertips. Calculations, day logs, calibrations, and alarms are easy to see and access.

-

The default Overview gives users quick access

to real-time conditions, logs and readings -

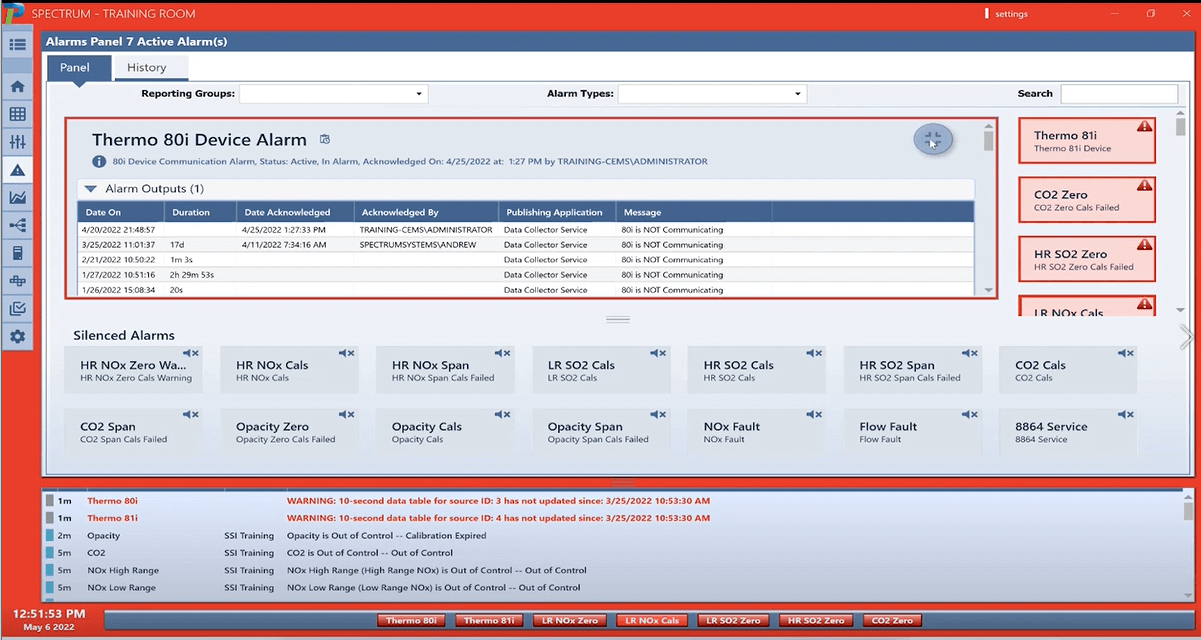

The Alarms panel provides an easy-to-read overview

that can be filtered by alarm type. -

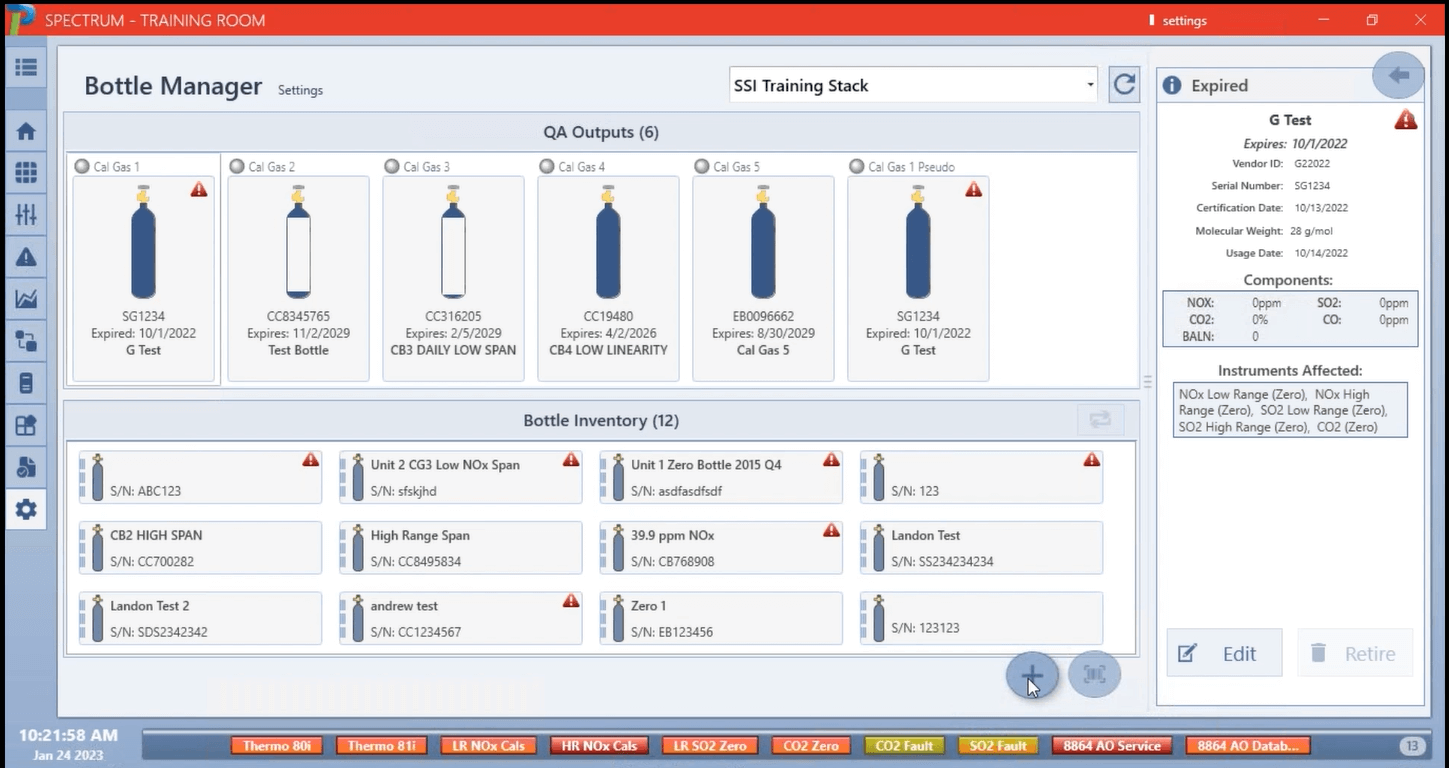

The Bottle Manager allows you to measure how accurate

CEMS analyzers are reading to make necessary adjustments. -

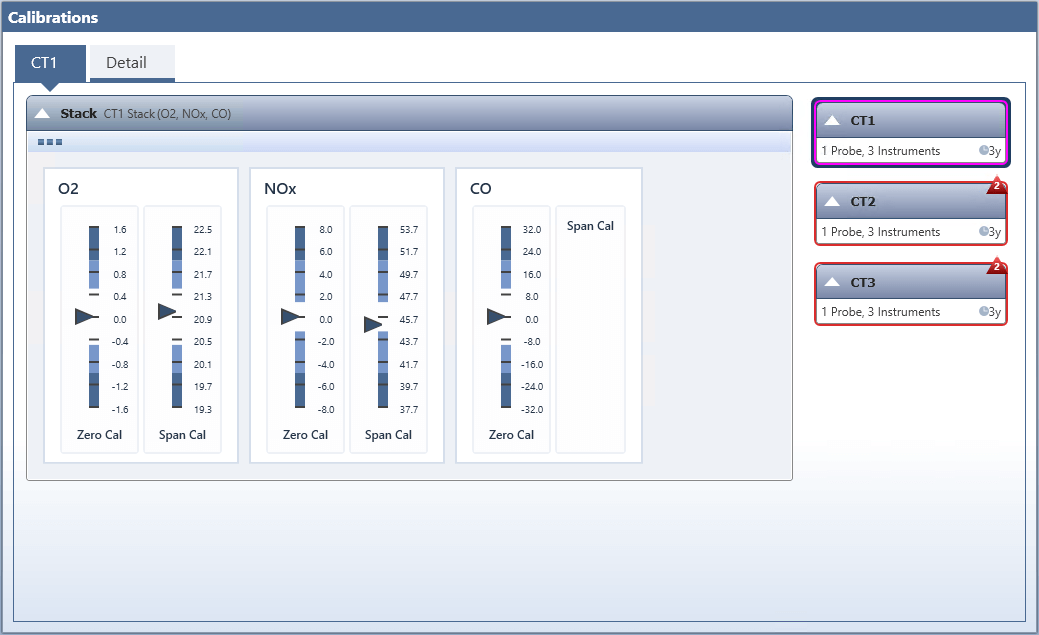

The Progress and Status Dashboard allows you to see all

instruments involved in progress calibration and their status. -

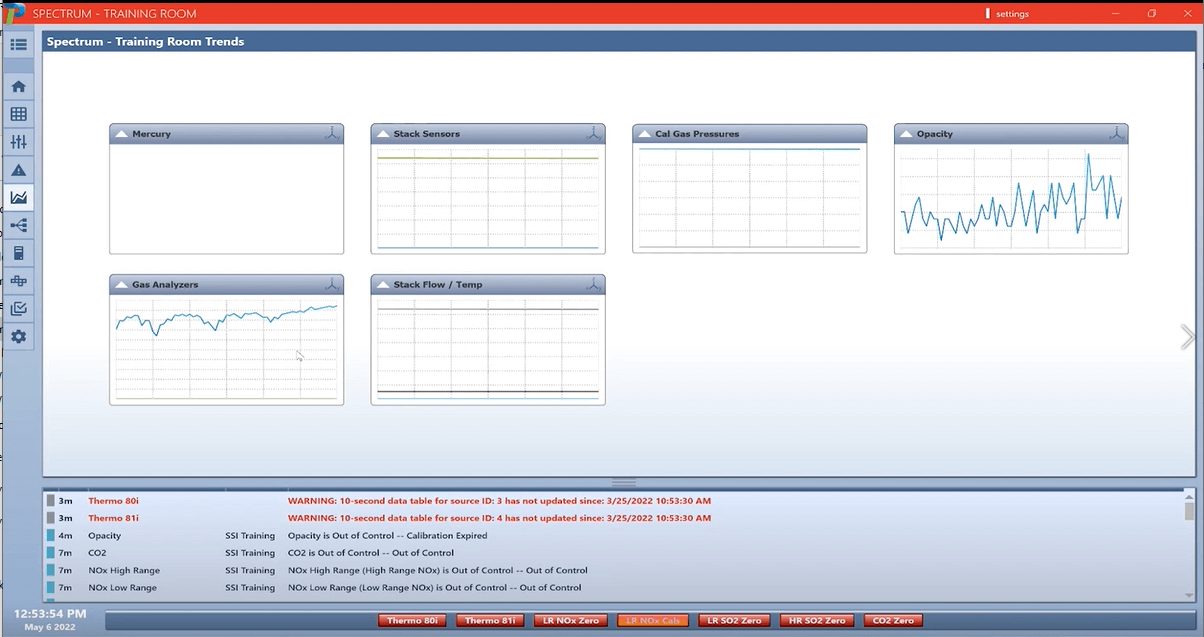

The Trends Dashboard provides user-configurable

charts to give a quick view of data trends. -

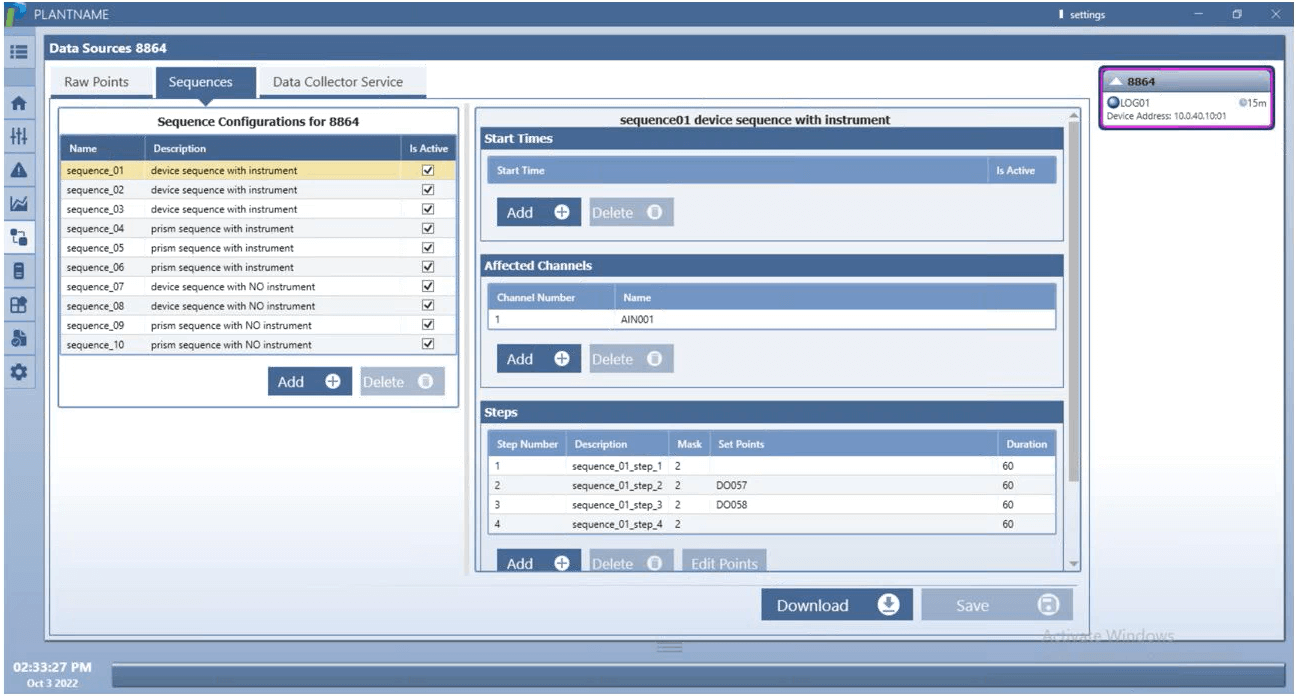

The Prism software works seamlessly with the reliable and robust 8864 Data Controller.

Prism software is supported by in-house, US-based customer support and continually updated to accommodate evolving needs.

Prism is backed by best-in-class customer support from a dedicated team of experts and is supported by online and in-person training.

The software is in constant development to meet the needs of customers, and keep pace with changes in regulations and technology. Our developers seek customer feedback via User Groups and software training courses.

We provide the training and resources you need to use Prism to its fullest potential.

Our tailored training from Prism experts ensures users managing emissions reporting are prepared and understand software best practices.

Training options include:

- User Group conferences

- Webinars

- Public and private training (in-person and online)

Michael is always very professional and knowledgeable.

I am always confident things will be resolved quickly with him.

Dave Patterson

Consulting Engineer (Air Quality Group), Ameren

ESC Spectrum has provided excellent engineering and procurement support.

Juan Cantu

Analyzer Specialist, ENglobal

Alex was very helpful in resolving the issues that I brought to him.

Kevin Bugay

Process Engineer, Cardinal Corporation

Even though we are only data logger users, the support staff has always been extremely nice,

very timely and completely knowledgeable on the topic at hand.

John Markely

Sr. Environmental Engineer, Kyger Creek

Very helpful, understood my issue and found the fix I needed.

Dane Ruberg

Instrument Technician, Xcel Energy

Scott is fantastic, very knowledgeable and very helpful!

Always know I am going to get the help I need when he answers the phone.

Celena Arreola

Environmental Engineer, El Paso Electric

Outstanding customer service!!!

Rick Gregory

IT Specialist/Network Admin, Calumet Specialty Partners

The customer service provided was quick and the agent sent additional information.

Ann Woods

Environmental Scientist, Agua Fria Generating Station

Excellent work!

Daniel Fefer

Contractor, Exelon

Case Studies

StackVision™ Case Study: New Orleans Power Station

Learn how the New Orleans Power Station used StackVision for Reciprocal Internal Combustion Engine (RICE)-specific monitoring and reporting.

StackVision™ Case Study: Petrochemical Plant

Learn how a Petrochemical plant used the StackVision Data Acquisition System for a +200K ROI by reducing Emergency Work Orders by 50%.

CEMS Solutions Case Study: O-I

Learn how the Owens-Illinois (O-I) glass manufacturer used ESC Spectrum’s full suite of CEMS solutions to meet air compliance challenges.