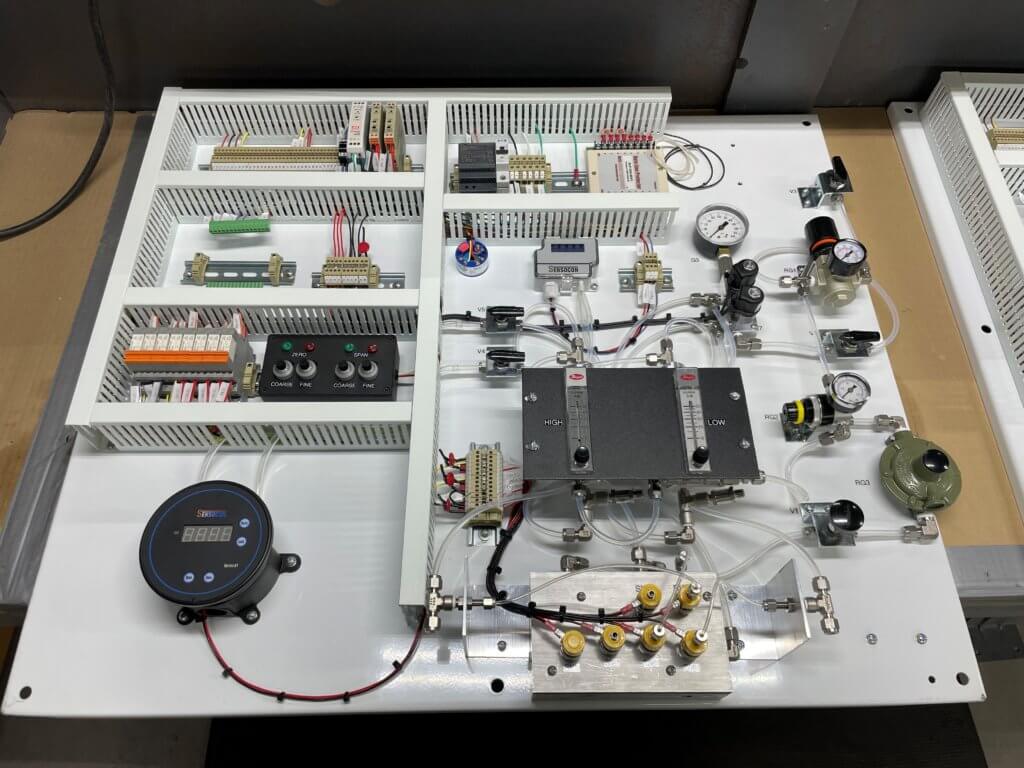

CEMFlow Compliance Stack Flow

Monitoring System

We offer a flexibile and expandable S-Type Pitot Tube gas flow monitoring system to help plants stay in compliance with their air emissions regulations

Constant Purge of Pitot Tubes

CEMFlow includes a constant low velocity purge through the pitot tubes. This prevents moisture interference and helps to prevent probe plugging problems.

Built-in Probe Check

CEMFlow has a built-in continuous check for probe plugging and an automatically initiated probe purge to clean the probe in the event of a blockage.

Onboard Primary Reference Manual Calibration Capability

The signal output is easily verified against standard EPA#2 methods via an onboard manometer. There is no need to ever send a system back to the factory for adjustment or re-calibration.

Low Installation and Initial Cost

The pitot sensor requires one sample port at one given level on the stack compared to other systems that require two sample ports at different levels. There are also no utilities necessary at the sample location.

Accurate Determination of Gas Flow Above 5 ft./sec.

This allows sources with high levels of static variation tobe monitored with a minimum of interference. Very hostile conditions can also be monitored without endangering the instrument package.

No Utilities at the Stack or Duct

Only the sensor is mounted on the stack or duct therefore CEMFlow can be operated in hazardous environments.

Fully Automated Calibration & Constant Purge

This offers completeunattended operation. Plugging is avoided by constant purging. In the event of a purge or calibration failure, an alarm is provided to notify an operator.

Robust In-Situ Sensors

Sensors are available in a wide range of desired materials designed to allow them to stand up to corrosion, high temperatures, and other hostile environments.

+99.99% Uptime

With no moving parts or electronics exposed to the elements up on the stack, CEMFlow offers unparalleled performance and reliability.

Ease of Maintenance & Low Cost

There are no blower assemblies or filters at the sample location. The unit may be serviced with nothing more than a test meter and lower-leveltechnical support. Pitot tube technology utilizes solenoids, a simple power supply, DP cell, commonly used pressure switches and regulators, manometer, and an easily interchangeable control unit –all relatively inexpensive.

Simple and User-Friendly yet Sophisticated Controller

Everyday functions can be accessed and performed without the need to reprogram the controller, including Purge Frequency, Calibration Time, and Calibration Frequency.

- Built-in RATA Function: easily turn off calibrations and purges during a RATA test.

- Password Protected Menus: prevents unauthorized changes in calibration times and durations.

- Built-in HELP Feature: allows an operator to view parameters without gaining access to change them.

- Wet Basis Calculations: the controller calculates the volumetric flow rate to standard conditions on a wet basis.

- External Calibration Control: calibrations can be controlled from an external source (i.e. PLC).

Meet Key Suppliers

ESC Spectrum partners with key Continuous Emissions Monitoring (CEM) and process control suppliers to ensure our customers have access to the right equipment for their facility’s application.

Michael is always very professional and knowledgeable.

I am always confident things will be resolved quickly with him.

Dave Patterson

Consulting Engineer (Air Quality Group), Ameren

ESC Spectrum has provided excellent engineering and procurement support.

Juan Cantu

Analyzer Specialist, ENglobal

Alex was very helpful in resolving the issues that I brought to him.

Kevin Bugay

Process Engineer, Cardinal Corporation

Even though we are only data logger users, the support staff has always been extremely nice,

very timely and completely knowledgeable on the topic at hand.

John Markely

Sr. Environmental Engineer, Kyger Creek

Very helpful, understood my issue and found the fix I needed.

Dane Ruberg

Instrument Technician, Xcel Energy

Scott is fantastic, very knowledgeable and very helpful!

Always know I am going to get the help I need when he answers the phone.

Celena Arreola

Environmental Engineer, El Paso Electric

Outstanding customer service!!!

Rick Gregory

IT Specialist/Network Admin, Calumet Specialty Partners

The customer service provided was quick and the agent sent additional information.

Ann Woods

Environmental Scientist, Agua Fria Generating Station

Excellent work!

Daniel Fefer

Contractor, Exelon

Case Studies

StackVision™ Case Study: Calumet Refinery

Learn how Calumet refinery used the StackVision DAS for flare monitoring and compliance with the Refinery Sector Rule (RSR).

StackVision™ Case Study: Pfizer Groton

Learn how the StackVision data acquisition system (DAS) helped Pfizer Groton comply with air regulations more efficiently.

StackVision™ Case Study: Delek-Tyler Refinery

Learn how the Delek-Tyler, TX refinery employed the StackVision Data Acquisition System to solve their complex needs and comply with RSR regulations.