8864 Data Controller EX

The hard-working

8864 Compact Data Controller EX

accurately and securely acquires, stores and

protects CEMS data in Class 1 Division 2 environments.

The 8864 Data Controller EX is ideal for Petrochem and Refining environments.

The 8864 Data Controller EX is built for a Class 1, Division 2 environment as an alternative to communicating via PLC when using ESC Spectrum’s Data Acquisition Systems.

It provides a reliable and powerful hardware bridge between StackVision™, Prism®, or other Data Acquisition System (DAS) software and an emissions monitoring rack.

The 8864 Data Controller EX is ideal for hazardous locations, including Petrochem and Refining environments.

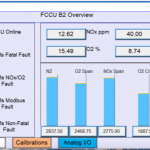

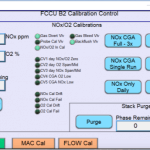

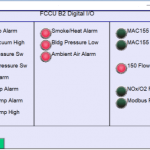

The Unit Features a Customizable, Easy-to-Read Display

Each unit comes with a customizable, programmable screen that showcases both analog and digital signals from the Data Controller, offering a pre-programmed standard template that can be tailored to your specific needs.

Backed by best-in-class customer support and services that keep the 8864 running smoothly.

The 8864 Data Controller EX is backed by best-in-class customer support from a dedicated team of experts and is supported by online and in-person training.

Our DAS services teams are standing by to support additional needs. The DASProtect support and maintenance services program ensures round-the-clock support, access to knowledge base articles, discounted services, training, software upgrades, and more.

We provide the training and resources you need to use the 8864 Data Controller EX to its fullest potential.

Our tailored training ensures 8864 Data Controller EX users are prepared and understand hardware best practices.

Training options include:

- User Group conferences

- Webinars

- Public and private training (in-person and online)

- StackVision Customer Success Program

Flexible Interface and Reliable CEMS to DAS Communication

The device features 8 physical inputs and 8 physical Digital I/O points, with up to 999 total, including pseudo I/O bits. Two built-in USB ports allow connection to external keyboards or mice and a convenient method to upgrade firmware. The Data Controller EX and EX-P do not use additional I/O cards.

The 8864 Data Controller communicates via Dual Gigabit Ethernet Interfaces independently and simultaneously with an instrumentation or CEMS network and with a StackVision server that may be located on the corporate business network. Each network port can support multiple sessions of data polling and remote user interaction — all while the 8864 continues to collect, compute, and store new data.

Michael is always very professional and knowledgeable.

I am always confident things will be resolved quickly with him.

Dave Patterson

Consulting Engineer (Air Quality Group), Ameren

ESC Spectrum has provided excellent engineering and procurement support.

Juan Cantu

Analyzer Specialist, ENglobal

Alex was very helpful in resolving the issues that I brought to him.

Kevin Bugay

Process Engineer, Cardinal Corporation

Even though we are only data logger users, the support staff has always been extremely nice,

very timely and completely knowledgeable on the topic at hand.

John Markely

Sr. Environmental Engineer, Kyger Creek

Very helpful, understood my issue and found the fix I needed.

Dane Ruberg

Instrument Technician, Xcel Energy

Scott is fantastic, very knowledgeable and very helpful!

Always know I am going to get the help I need when he answers the phone.

Celena Arreola

Environmental Engineer, El Paso Electric

Outstanding customer service!!!

Rick Gregory

IT Specialist/Network Admin, Calumet Specialty Partners

The customer service provided was quick and the agent sent additional information.

Ann Woods

Environmental Scientist, Agua Fria Generating Station

Excellent work!

Daniel Fefer

Contractor, Exelon

Case Studies

StackVision™ Case Study: New Orleans Power Station

Learn how the New Orleans Power Station used StackVision for Reciprocal Internal Combustion Engine (RICE)-specific monitoring and reporting.

StackVision™ Case Study: Petrochemical Plant

Learn how a Petrochemical plant used the StackVision Data Acquisition System for a +200K ROI by reducing Emergency Work Orders by 50%.

CEMS Solutions Case Study: O-I

Learn how the Owens-Illinois (O-I) glass manufacturer used ESC Spectrum’s full suite of CEMS solutions to meet air compliance challenges.