Understanding the 8864 Data Controller

The 8864 Data Controller is a microprocessor (computer) device designed to collect, store, and analyze data from various analyzers and CEMS instruments. It serves as the central hub for managing critical data related to environmental parameters.

Features

- A user-friendly interface that uses plain language prompts.

- Easy data entry with support for arrow and backspace keys, insert and overstrike modes.

- Compatibility with various channel types, including math packs, stream-switching, time-on-line counters, rolling averages, and optional meteorological parameters.

- Simple and advanced calibration programs for both ease of use and flexibility.

- Full-screen real-time displays of data values.

- Graphical representation of data in real-time and historical formats (available on LCD screens only).

- A flexible alarming system with no limitations on the number of alarms for each channel.

What Does the 8864 Data Controller Do?

- Translate analog signals into data values and construct averages

- Validate data based on regulation requirements

- Store average data in multiple average intervals

- Initiate daily calibrations and store calibration data

- Perform calculations

- Assign flags

- Trigger alarms

- Transfer data values to and receive configuration data from the StackVision Server

- Handle any necessary control functions (e.g., triggering a valve or switch)

- Report status and controller alarm conditions to the StackVision server

Basic Anatomy of the 8864 Data Controller

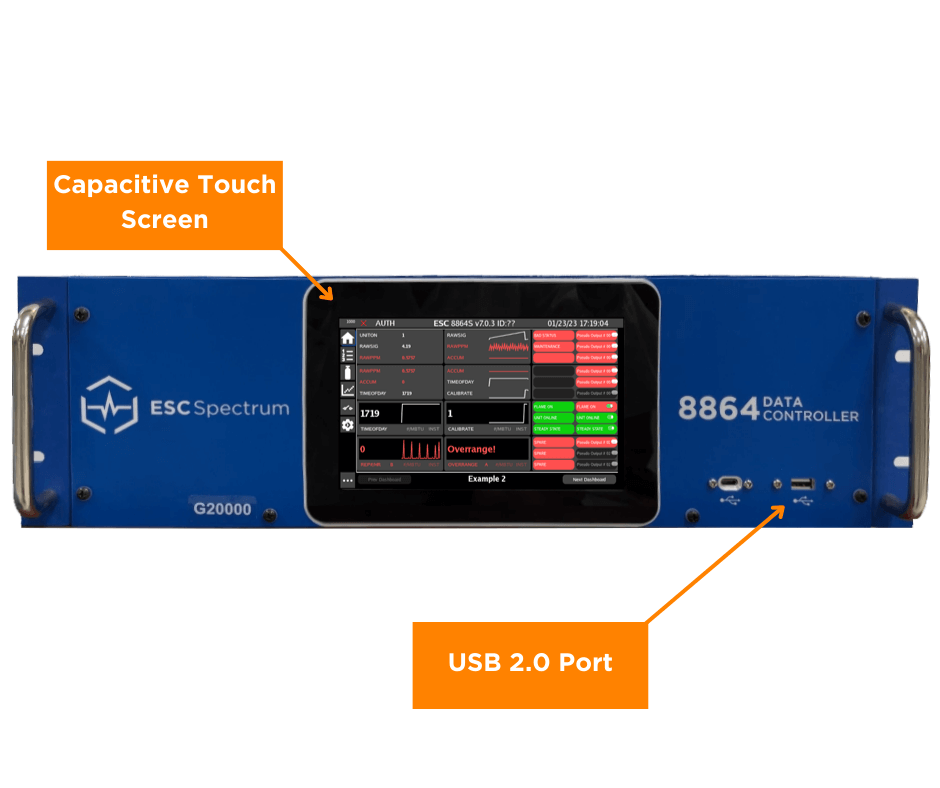

Front View

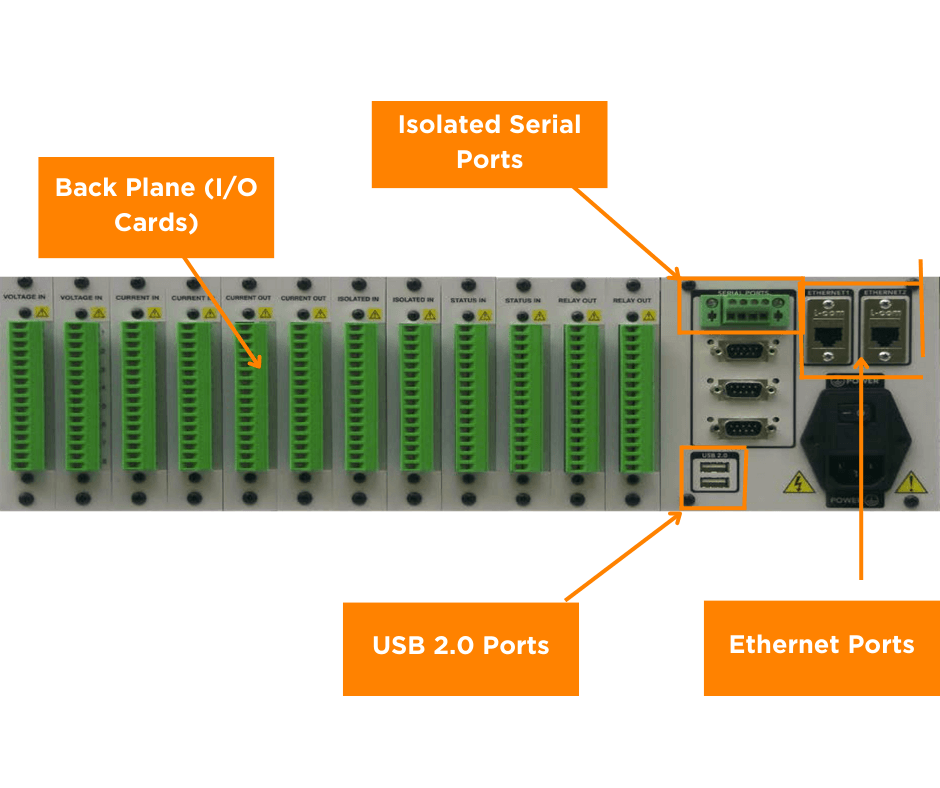

Rear View

What Are The Best Practices to Maximize Its Potential?

Configuration and Setup

One of the first steps in using the 8864 Data Controller is proper configuration. Setting up IP addresses, subnet masks, and gateways correctly is essential. Ensure that the data controller's network settings align with your facility's network topology.

Know Your Network Topology

Understanding your local network topology is crucial. Identify any routers, firewalls, or network address translation (NAT) that may impact communication. Collaborate with your IT department to ensure the right configurations are in place.

Tools for Troubleshooting

The 8864 Data Controller offers built-in tools to help diagnose communication issues. These include ping tests, TCP tables, and the ability to capture Modbus traffic for detailed analysis. Familiarize yourself with these tools for efficient troubleshooting.

Ping Tests

Use ping tests to check whether the Data Controller responds to ping requests and if it can successfully ping other devices. This simple test can help verify network connectivity.

TCP Tables

TCP Tables can provide critical insights into the state of TCP/IP connections. Understanding what each state means and monitoring this information can help you identify communication issues and resolve them effectively.

TCP/IP Capture

Consider using network analysis tools like Wireshark to capture and analyze Modbus traffic. It allows you to monitor inbound requests for data, helping you diagnose potential issues with your Modbus configuration.

Modbus Troubleshooting

Modbus is a common protocol for industrial applications. If you're dealing with Modbus communication problems, take advantage of the 8864 Data Controller's ability to capture and analyze Modbus commands.

Watch our more in-depth webinar to learn the best practices listed above for more details.

Conclusion

The 8864 Data Controller is a tool for managing environmental data in a variety of industries. By following best practices for configuration, network understanding and utilizing built-in diagnostic tools, you can ensure the Data Controller operates efficiently and reliably. Troubleshooting communication issues is made more manageable with the tools and practices discussed, helping you maintain a smooth and efficient data monitoring system.

Interested in learning a more comprehensive overview of how CEM Systems work? Read Understanding Continuous Emissions Monitoring Systems (CEMS): A Comprehensive Guide. This guide will give you a complete understanding of all the components in the flow of a CEMS including how a data controller plays a part.

How Can ESC Spectrum Help?

We proudly offer a comprehensive suite of services designed to ensure your 8864 Data Controller operates at its peak performance, safeguarding your operations and regulatory compliance. With ESC Spectrum’s assistance, you can trust that your 8864 Data Controller will continue to run smoothly without missing a beat.

For additional assistance or questions, please don’t hesitate to reach out to us. Make the most of this powerful hardware to enhance your facility’s air emission data monitoring.

Taylor Hempel - Marketing Specialist II

Taylor Hempel is a skilled marketer specializing in content creation, social media management, and driving customer engagement. With a BBA in Marketing from the University of Texas at San Antonio, she joined ESC Spectrum in February 2022. Taylor is adept at crafting informative content about continuous emissions monitoring systems, its components and data acquisition systems allowing her to craft content that educates and informs industry professionals.