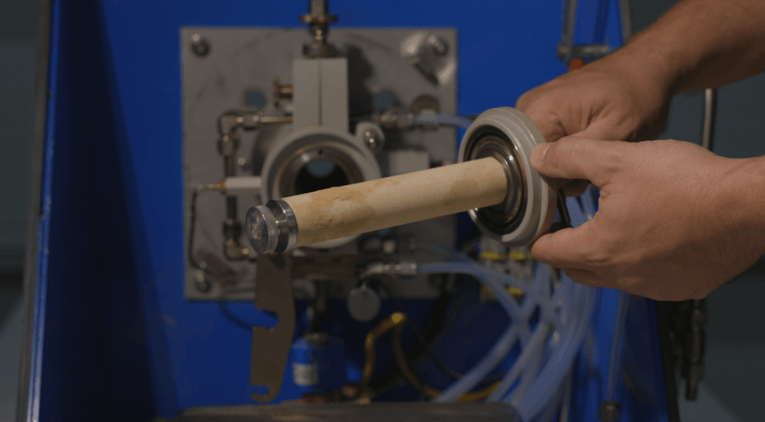

The continuous emissions monitoring probe is the initial contact with the sample being drawn for monitoring. It is also the separation point of the sample gas, purge air, and calibration gas. Its primary function is to provide a heated environment to maintain sample gas temperatures above the stack dewpoint and remove particulate material from the gas sample. Preventive CEMS probe maintenance can help keep your probe functioning and provide you with years of reliable data and service.

These probes influence the entire CEM system’s integrity. Neglecting can lead to contamination, inaccurate readings, and regulatory compliance issues. Routine maintenance will help keep your probe functioning and ensure:

- Reliable, accurate emissions data

- Reduced downtime and associated costs

- Extended equipment lifespan

- Compliance with EPA regulations and audit readiness

How Often Should You Service Your CEMS Probe?

The ideal maintenance frequency depends on your facility’s operational conditions. Our Field Service Technicians recommend inspecting probes:

- Annually: Standard recommendation for extractive and dilution systems

- Quarterly: Best for high-use or high-contaminant environments

- Event-Driven: Required post data anomalies, regulatory shifts, or equipment changes

Extractive Probe Maintenance & Common Issues

We recommend the following steps during an annual probe maintenance service or an extractive system:

Annual Probe Maintenance Service

- Shut off extraction pump

- Remove filter lid; replace O-rings

- Swap out filters and packing

- Restart extraction pump

- Run auto-calibration

Troubleshooting Common Extractive Probe Issues

The top two common issues that affect extractive CEMS probes are:

- Loose Umbilical Connection: This can cause a diluted sample due to mixing with ambient air.

- Leaking O-Rings: When the O-rings start to leak, the Oxygen reading will typically go high compared to the normally expected readings. This will happen during calibrations as well as during normal operation.

Dilution Probe Maintenance & Common Issues

We recommend the following steps during an annual probe maintenance service for a dilution system:

Annual Probe Maintenance Service

- Power down probe air supply

- Remove filter lid; replace O-rings

- Replace filters and packing

- Rebuild dilution/bypass block

- Power on air supply; calibrate

Troubleshooting Common Dilution Probe Issues

The top two common issues that affect dilution CEMS probes are:

- Clogged or Cracked Critical Orifice: A clogged orifice can result in lower sample readings, and a cracked critical orifice can result in a higher-than-usual reading.

- Clogged Stinger Tube: The result is that little to no sample will get to the analyzer.

Key Takeaway

By establishing a routine maintenance schedule and knowing what to look for during inspections, you can avoid costly surprises and keep your system running smoothly.

Need help maintaining your CEMS probes or tracking persistent issues? ESC Spectrum offers complete CEMS maintenance services, including probe inspection, part replacements, and onsite support from experienced technicians.

Interested in learning a more comprehensive overview of how CEM Systems work? Read Understanding Continuous Emissions Monitoring Systems (CEMS): A Comprehensive Guide. This guide will give you a complete understanding of all the components in the flow of a CEMS.