When selecting a portable gas analyzer for measuring emissions, it is essential that you are equipped with the knowledge that not all units are created equal. Selecting your portable gas analyzer matters most when using it as a Continuous Emissions Monitoring System (CEMS), or, using it for an extended period (i.e., 1 – 12 hours non-stop).

Whether you already own a CEMS or need detailed emissions data for an exhaust stream, the type of portable CEMS you use can make an enormous difference in your results. This guide will cover the important issues you need to understand regarding portable CEMS.

Checking a CEMS with a Portable Gas Analyzer

One mistake that you can make would be using a portable gas analyzer to verify or check their CEMS readings. This has caused many repeat Stack Tests (at a great expense) because a portable analyzer’s readings did not match up with the readings of a CEMS.

Having a CEMS means you have an accurate and precise way to measure low concentrations of exhaust gases in hot and wet sample streams. Having a portable CEMS analyzer can often mean you can measure “approximate” concentrations in hot-wet exhaust streams—and the higher the concentration, the better.

Why Doesn’t a Portable Analyzer Measure as Accurately?

One word—technology. One of the most frequently used and least expensive technologies that portables utilize is electrochemical. An electrochemical is a device capable of generating electrical energy from chemical reactions. These chemical reactions produce a current that is directly proportional to the gas concentration.

To their credit, these sensors can be very sensitive at targeting gas and can measure down to part per million (ppm). They are ideally suited for “fixed” gas detection (i.e., ambient monitoring to alert when leaks occur). They are also good for quick generalized readings or spot checks in a stack or process. Where they fall short is when they are used for continuous detection. This is for several reasons:

As the chemical catalyst in the cells is consumed, the properties of the cell change. Constant re-calibration may be required to maintain accurate readings.

Humidity and moisture levels can affect the chemical catalyst. As the cell dries out, or conversely, absorbs moisture, the properties change, potentially requiring calibration tweaks.

Operating in low oxygen environments alters sensor performance when the target gas’s oxidation occurs at the sensing electrode. That can occur for specific ammonia, carbon monoxide, and hydrogen sulfide electrochemical cells.

Reading very low levels (i.e., sub 20 ppm) accurately is not typically possible for these types of cells. Most portables will have CO ranges only down to 0-1,000 ppm. Reading 10-20 ppm on a scale of 0-1,000 is problematic. Typically less than 10% of the scale can be in the noise area of an analyzer, and it is much less accurate or reliable than a non-portable CEMS.

Calibration bottles typically used to check portable analyzers have a ±10% accuracy. If a 0-1,000 ppm scale is off by up to 100 ppm, imagine how accurate a 9 ppm reading will be.

The largest detriment to continuously running a portable analyzer with electrochemical technology is usually the accuracy of readings of the gas stream being measured. Most emissions sources, and many process sources, run at elevated temperatures and contain moisture.

If a sample is extracted, it will cool and condense. That process leaves an excess of moisture behind in the cells. The condensation changes the measurement properties and can eventually saturate the cells, rendering them non-operable. Short measurement times are usually recommended for this reason.

Many portable units come with a hygroscopic moisture removal device, but they are usually tiny and, again, not meant for long measurement. Often, too much moisture can clog the filters and/or overwhelm an internal pump.

Another issue presented is the gas stream itself. If corrosive gases or other gases that react with the cell chemistry are present, it can affect readings and the instruments’ ability to operate properly.

Overall, Electrochemical Portables are relatively inexpensive, good for quick measurements in an exhaust gas stream or for high-level concentrations, and not ideal for long-term sampling, low-level concentrations, or high accuracy and precision.

The Solution: A True Portable CEMS

So, how do you conduct longer-term exhaust or process stream measurements when you need accurate and reliable results? If a manufacturer calls their portable gas analyzer a “CEMS,” it must address the issues above with the hot-wet sample handling and the measurement technology. Here’s what to look for and how these issues are addressed.

Sample Handling

Even though it’s “portable,” a portable CEMS will still need a robust front-end sampling system. The best unit will have a heated probe and heated umbilical (sample tubing) for delivering the sample to the analyzer portion of the instrument.

The prove and umbilical will act to keep the sample above the dewpoint and prevent condensation. Besides preventing the formation of unwanted condensation and clogging, it also prevents premature removal of target gas during condensation formation.

The sample conditioner is next in line before the analyzer is particle and moisture removal and cooling of the sample. In the best-case scenario, this is accomplished with various components:

- Multiple water scrubbers

- Charcoal Scrubber

- Inline Fine Particulate Filter (0.3µm) and Micro-fine Dust Filter (0.2µm)

- Thermo-electric Chiller using Peltier Cooling with Peristaltic Pump for Continuous Moisture Removal

- Diaphragm-type Sample Pump with Temperature Alarm

- Flowmeter for accurate control of sample

All the above components work together to deliver a clean and dry sample to the Portable Analyzer. They also ensure the ability to sample “continuously” without moisture saturation, plugging, and other issues.

Measurement Technologies

The best portable analyzer for low-level continuous gas measurement will not utilize electrochemical cells (although Oxygen cells are sometimes used). Technologies that measure accurately and precisely will be utilized and will offer much higher reliability and minimal maintenance. Depending on the target gas, multiple technologies will also be utilized, as different technologies are more specific and ideal for different gases.

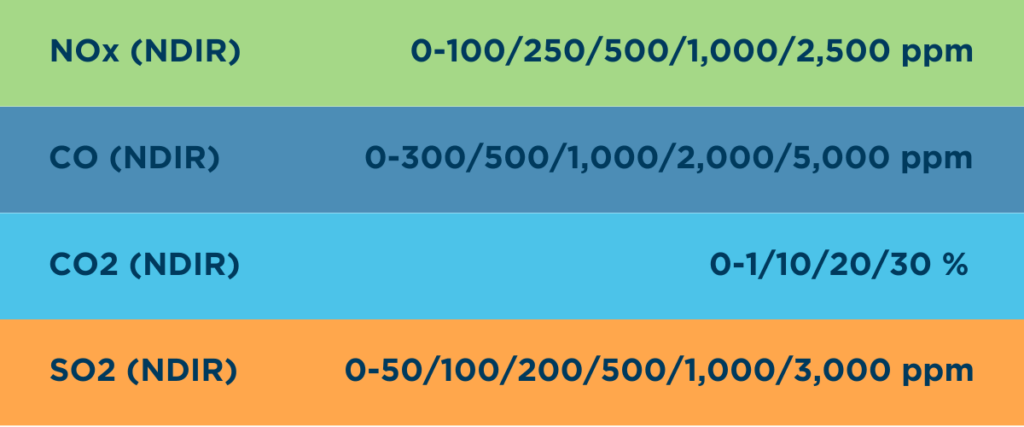

NDIR: Non-Dispersive Infrared technology is commonly used for NOx (Nitric Oxides), CO (Carbon Monoxide), and CO2 (Carbon Dioxide). In the simplest sense, using an infrared light source, the detector measures the absorption of light at wavelengths specific to the target gas.

These analyzers are accurate, precise, and repeatable. They are also very stable and do not change characteristics over their run time. Since the gas going through the detector has been cleaned and dry, there is very little impact on the optics with regard to dirt and corrosion (thereby reducing maintenance requirements).

The key is the ability to measure accurately across many more and lower ranges. Here are some typical ranges:

SO2 (Sulfur Dioxide) is measured with NDUV (non-dispersive ultraviolet) technology. This works similarly to the NDIR except that ultraviolet waves are absorbed instead of IR light. Again, the advantage is in the ranges achievable.

For example: for Oxygen, electrochemical cells are often used as they are the most stable of these types of cells. The measurements are almost always in Percent (%) ranges where high precision is not as critical. Another technology called Paramagnetic can be utilized for more accurate measurements.

Unlike electrochemical sensing technologies, a Paramagnetic cell never needs changing. Its performance never deteriorates over time, reducing ongoing maintenance requirements and delivering a long operational life. The most common Oxygen range is 0-25%, but ranges of 0-5% and 0-10% are also available.

For difficult gases like HCl (Hydrogen Chloride), NH3 (Ammonia) & CH4 (Methane), Tunable-Diode Laser (TDL) is a technology that offers uncompromised measurement performance. In this case, the analyzer measures the absorption of specific laser light wavelengths.

In Conclusion

Portable and temporary ways to measure exhaust and process gases are available in the market. Using good sampling techniques and the proper measurement technologies, it’s possible to sample for long periods of time (hours) and obtain accurate and reliable results. The typical simple combustion analyzer, while having its advantages, is not the device for this type of service.

ESC Spectrum Portable CEMS Services

At ESC Spectrum, we offer customized solutions, including parts from major emission monitoring manufacturers and the expertise needed to repair, maintain, and upgrade your CEMS analyzers.

Contact us today to get an accurate quote for any of our CEMS Services.

Interested in learning a more comprehensive overview of how CEM Systems work? Read Understanding Continuous Emissions Monitoring Systems (CEMS): A Comprehensive Guide. This guide will give you a complete understanding of all the components in the flow of a CEMS.