A Data Acquisition System (DAS) is the backbone of a facility’s emissions monitoring and compliance efforts. Upgrading a DAS isn’t just about keeping up with technology—it’s about making operations smoother, staying compliant, ensuring the software meets current cybersecurity standards, and saving time and money. Whether replacing an outdated system, meeting new regulations, or improving efficiency, the right DAS can make a large impact.

Why Facilities Upgrade Their DAS

Switching from a Competitor's System

Many facilities switch to a new DAS due to poor support, limited visibility, and a lack of control over their current system. Many vendors use a “black box” setup, which often restricts user’s access to settings and calculations, making troubleshooting difficult and limiting flexibility. When issues arise, slow response time and lack of knowledgeable assistance can lead to compliance risks and increased frustration.

How an Upgrade Helps:

- StackVision allows users to adjust configurations without restrictions, giving them full control over system settings and making adjustments easier.

- StackVision offers detailed visibility into system configurations, ensuring transparency in how calculations are performed.

- Better customer support means problems get solved quickly by knowledgeable experts who understand both the system and regulatory requirements.

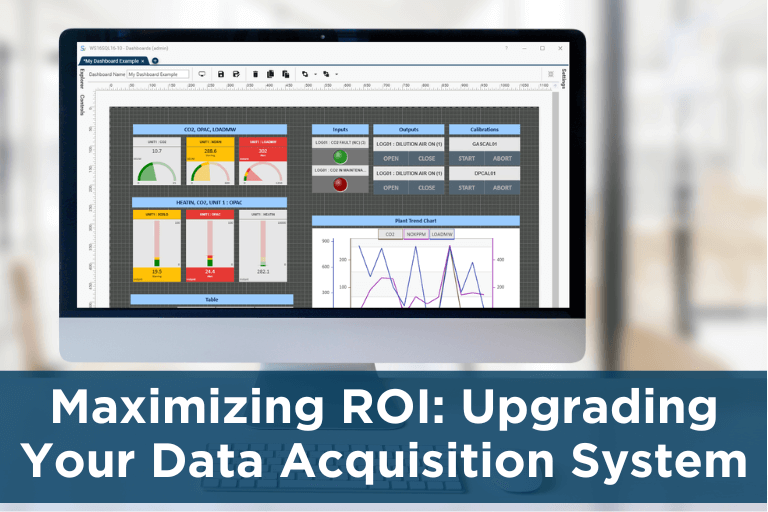

- A modern interface improves usability and efficiency by allowing users to configure dashboards to include fleetwide system data, active alarms, and exceedance limits.

ROI: Improved data visibility, more reliable data collection, and a system that works the way it should with fewer headaches.

Installing a DAS for Previously Unmonitored Units

New regulatory requirements in many industries—such as MATS Residual Risk, GHG Performance Standards, and RSR requirements—often require installing a DAS on certain units. Many facilities start with a single monitored unit but later find that expanding DAS coverage makes reporting easier.

Common Challenges Without a DAS:

- Spreadsheets can be unreliable and hard to verify.

- Performing required calculations manually is time-consuming.

- Multiple reporting systems create unnecessary complexity.

- Documentations of algorithms for the EPA

- Hard to meet requirements to report, retain, and make data available.

How an Upgrade Helps:

- A centralized DAS automates calculations and reporting.

- View fleetwide system data in one location and in real time.

- The system scales as needs grow.

ROI: Less manual work, reduced compliance risks, and a system that grows with the facility.

Monitoring Method Changes Due to Operational Shifts

If a plant starts using a new fuel type or changes how emissions are monitored, the DAS must be updated to reflect those changes.

How an Upgrade Helps:

- Configurations can be adjusted to meet new requirements.

- The system can handle more complex reporting needs.

ROI: Compliance stays intact, and the plant gains flexibility in how it operates.

How DAS Upgrades Improve Efficiency

Permit Compliance & Audits

New permits, audits, or personnel changes often require a fresh look at how a DAS is configured. Issues can arise when a system isn’t properly set up to meet permit conditions.

How an Upgrade Helps:

- Experts can review the system and make necessary updates.

- Audits become easier with accurate and well-documented data.

ROI: Fewer compliance issues and peace of mind that everything is in order.

Replacing Old or Unsupported Equipment

Technology doesn’t last forever. As servers, analyzers, and other equipment age, performance declines, and security risks increase.

How an Upgrade Helps:

- Ensures servers are compatible with the latest software and in line with current operating systems.

- Upgraded analyzers improve accuracy and reliability.

- New features on an upgraded data controller, like dashboards for alarm and calibrations, make data easier to access.

ROI: A more reliable system that runs better and lasts longer.

The 8864 Data Controller Generation 2 works seamlessly with our StackVision DAS. Learn more about the 8864’s customizable dashboards, robust data storage, and a touchscreen interface.

Case Study: How One Refinery Saved $200K with StackVision

An integrated downstream petrochemical refinery was struggling with outdated emissions monitoring. Their existing system made it difficult to track alarms and required too much manual work. After installing StackVision, they:

- Automated data collection, reducing manual input errors.

- Gained remote access for monitoring and calibrations.

- Set up real-time alerts for pass/fail conditions.

As a result, energy work orders dropped by 50%, saving the refinery $200,000.

Is It Time to Upgrade?

If your current DAS is causing problems, struggling to keep up with compliance, or simply outdated, an upgrade could be the right choice for your facility. The right system can reduce inefficiencies, prevent costly issues, and make reporting easier.

Our Data Acquisition System (DAS), StackVision, is used by more than 3,100 air emissions sources for monitoring and reporting. Backed by US-based 24/7/365 customer support and online and in-person training, StackVision ensures round-the-clock support.

Want to see if StackVision would be a good fit for your facility?

Reagan Sokolosky - Marketing Specialist III

Reagan is a Strategic Communications graduate from Oklahoma State University who joined ESC Spectrum in April of 2020. She dove headfirst into the air emissions compliance industry with no prior experience. She has been writing and researching about air emissions for 4 years to educate our customers. Within four years, Reagan advanced to Marketing Specialist III, showcasing expertise in ESC Spectrum’s learning offerings, email marketing, video editing, product and software releases, and company rebranding.

Contact Reagan at rsokolosky@escspectrum.com for questions or comments.