What is an Extractive CEMS Umbilical?

The CEMS umbilical is a bundled set of tubes and wires that connects the sample probe, gas analyzers, and gas transport system. In this post, we will cover the entire construction of the umbilical, as well as dos and don’ts and tips for umbilical installation.

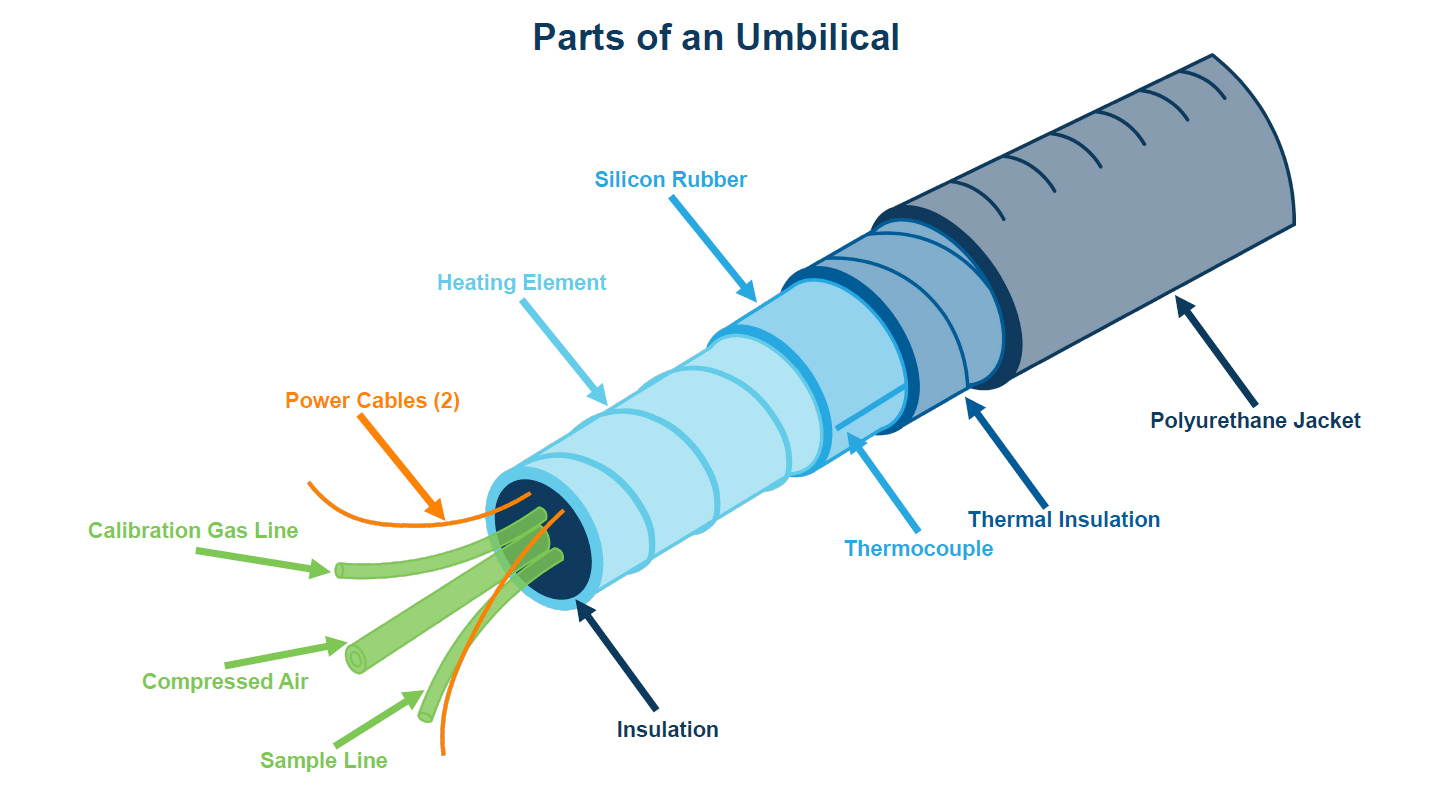

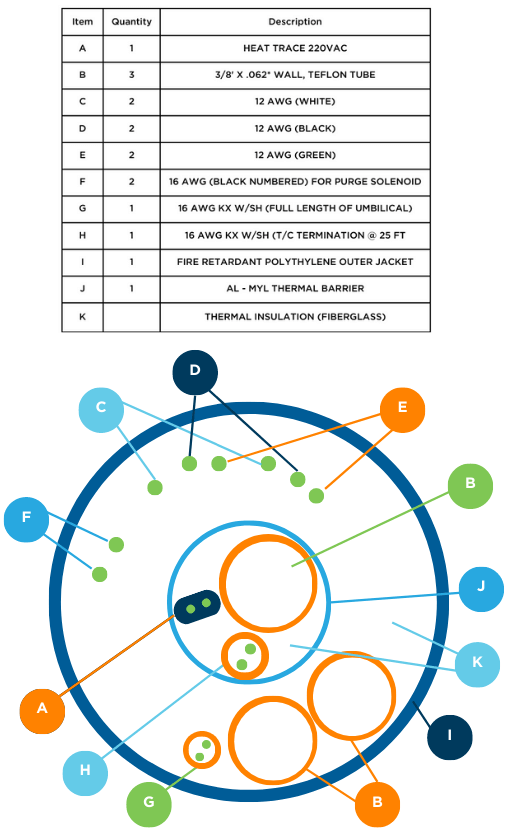

Construction of the Extractive CEMS Umbilical

Wiring

The umbilical includes wiring for the stack junction box and provides AC power to the probe and umbilical heaters, usually 115V and 24V.

Tubing

The umbilical typically includes the following tubes:

- One 3/8″ PFA Teflon tube for calibration gas to the probe

- One 3/8″ Teflon tube for the CEMS sample

- One 3/8″ PFA Teflon tube for instrument air and purge air

A spare tube can be added if needed. However, adding more than one may reduce the system’s ability to maintain temperatures above 80°F.

Insulation/Jacket

The tubing and wiring are wrapped in a thermal barrier made of aluminized Mylar. Around that is Aspen Aerogel insulation, which is about four times more effective than fiberglass. This allows for a smaller overall cable diameter while maintaining good thermal protection.

Heater

Two Type “K” thermocouples are built in to monitor the temperature of the umbilical and the probe heater. The heating system typically uses 18 watts per foot.

Heater nodes are spaced every 3 inches along the umbilical. Typical operating temperatures are between 250°F and 350°F, controlled by a unit located in the CEMS cabinet.

Installation

There are three key things to consider during installation:

- How the umbilical is secured

- Ensuring the correct length

- Preventing common issues

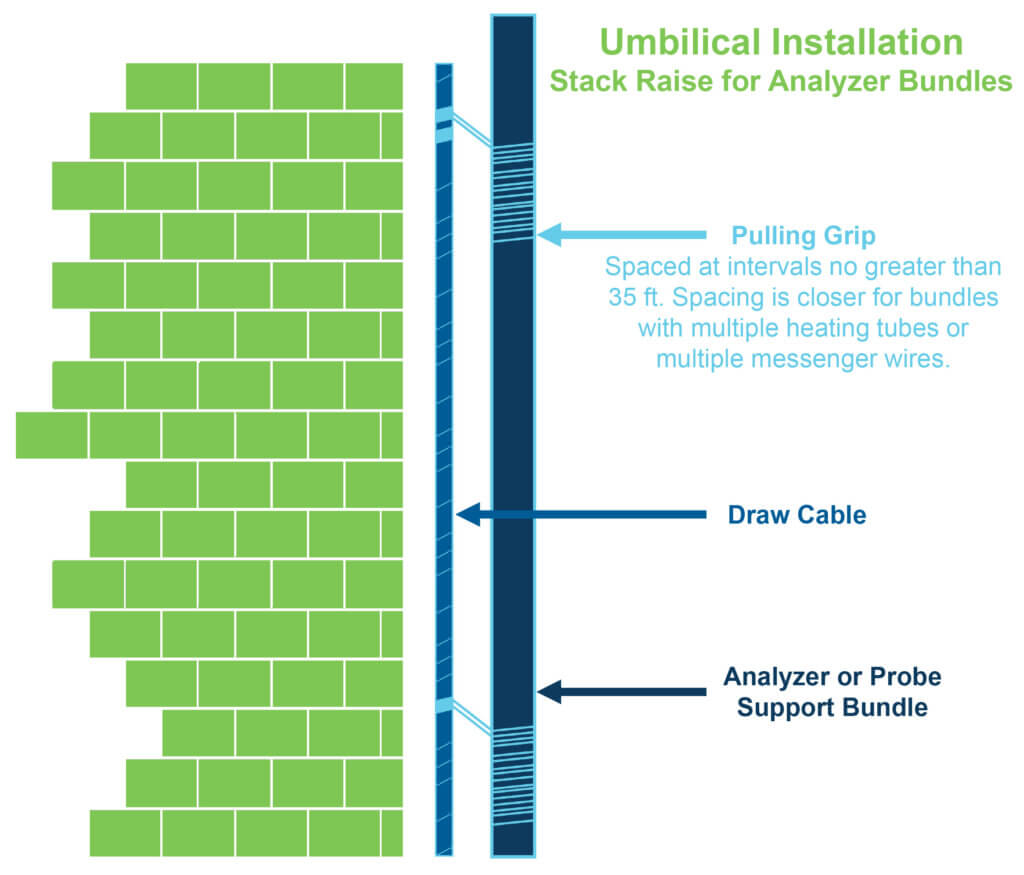

Securing the Umbilical

Leave enough slack at both ends to allow for proper connection and strain relief.

The umbilical must be supported every 10 feet for vertical runs and every 5 feet for horizontal runs.

Kellum grips are commonly used to attach the umbilical to the stack. These grips tighten under tension, similar to a Chinese finger trap. In some setups, conduit is used instead.

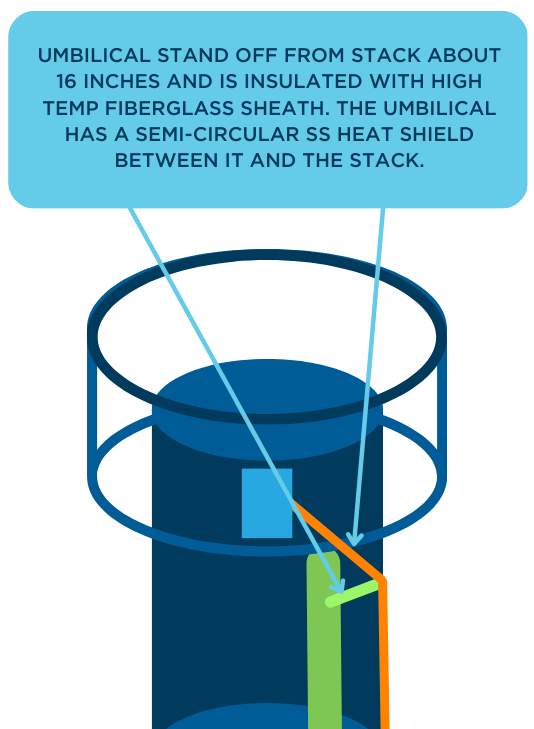

The coil of the Kellum grip wraps around the umbilical and is secured to the stack with a draw cable. This keeps the umbilical spaced away from the stack, protecting it from high temperatures.

Length

The required length depends on the specific installation. The minimum length that can be manufactured is 100 feet. An extra 10 feet on each end is recommended for installation.

The umbilical must be a single, continuous length. It cannot be spliced to extend the run.

If the total length exceeds 250 feet, a second power source is needed because the heater draws too much current for 14-gauge wire.

Longer umbilicals use two heater wires, each with its own power source.

Heater nodes are spaced every 3 feet. When cutting and terminating the umbilical, the installer should position a heater node as close to the exposed ends as possible. Unheated sections of the sample line can lead to condensation.

The umbilical has a designated stack end and CEMS cabinet end. It’s important to install it in the correct direction.

Potential Issues

Certain problems can arise if preventative action is not taken.

- The umbilical should always slope downward to prevent moisture from collecting. If a loop forms, water can build up and clog the sample line.

- Avoid exposing the umbilical to heat above 130°F. Higher temperatures can damage the outer layer.

- The PFA Teflon tubing may release small amounts of carbon monoxide (CO), which can interfere with CEMS readings, especially when measuring total hydrocarbons (THC) and low CO levels (under 5 ppm). To reduce this effect, stainless steel tubing is sometimes used instead of Teflon, or the system is purged with clean air at startup to remove CO. This purge is usually done at 350°F for 24 to 48 hours.

- When installing, make sure the bend in the umbilical is no tighter than a 30-inch radius to avoid pinching the sample line.

Umbilical Dos and Don'ts

Proper installation and handling of CEMS umbilicals are essential for reliable system performance and accurate emissions data. The chart below outlines key practices to follow—and avoid—when working with umbilicals to ensure long-term durability and compliance.

| Dos | Don’ts |

| ✅ Verify the design and length | ❌ Make guesses (design, length) |

| ✅ Consider ambient temperature and if it is right for your environment. | ❌ Assume prints are updated |

| ✅ Specify maintain temperature | ❌ Install umbilical “upside down”

|

✅ Plan ahead for installation

| ❌ Lose your termination kits |

| ✅ Order termination kits and boots for secure connection on both ends | ❌ Have any uphill runs or loops |

✅ Oversee installation

| ❌ Avoid asking questions when you are unsure about installation |

Maintenance

While there is usually no maintenance on an umbilical, some applications might require periodic cleaning. Acetone can be flushed through a sample tube to clean out any residue that forms and collects. In these cases, an additional tube can be convenient so as not to disrupt monitoring.

How Can ESC Spectrum Help?

Interested in learning a more comprehensive overview of how CEM Systems work? Read Understanding Continuous Emissions Monitoring Systems (CEMS): A Comprehensive Guide. This guide will give you a complete understanding of all the components in the flow of a CEMS.

Whatever your CEMS and umbilical needs may be, ESC Spectrum is committed to finding best solution for your facility.