Does Your CEMS Need Upgrading?

If your facility uses a Continuous Emission Monitoring System (CEMS), it’s probably crossed your mind that you’ll need to upgrade its parts. After all, one thing that you can count on with any piece of equipment is an eventual failure.

Will you ever need to replace the whole CEMS cabinet? Probably never.

Almost 95% of CEMS were built using a “modular” approach in the last few decades. Meaning, the Continuous Emission Monitoring System (CEMS) is made up of many individual components that are fitted together to create the entire system. With this approach, a CEMS should never need wholesale replacement.

You can replace each component as it fails or becomes outdated or off the market. This allows your facility to have a system that is up to date using the latest CEMS component technology.

How Does a Continuous Emission Monitoring System (CEMS) Work?

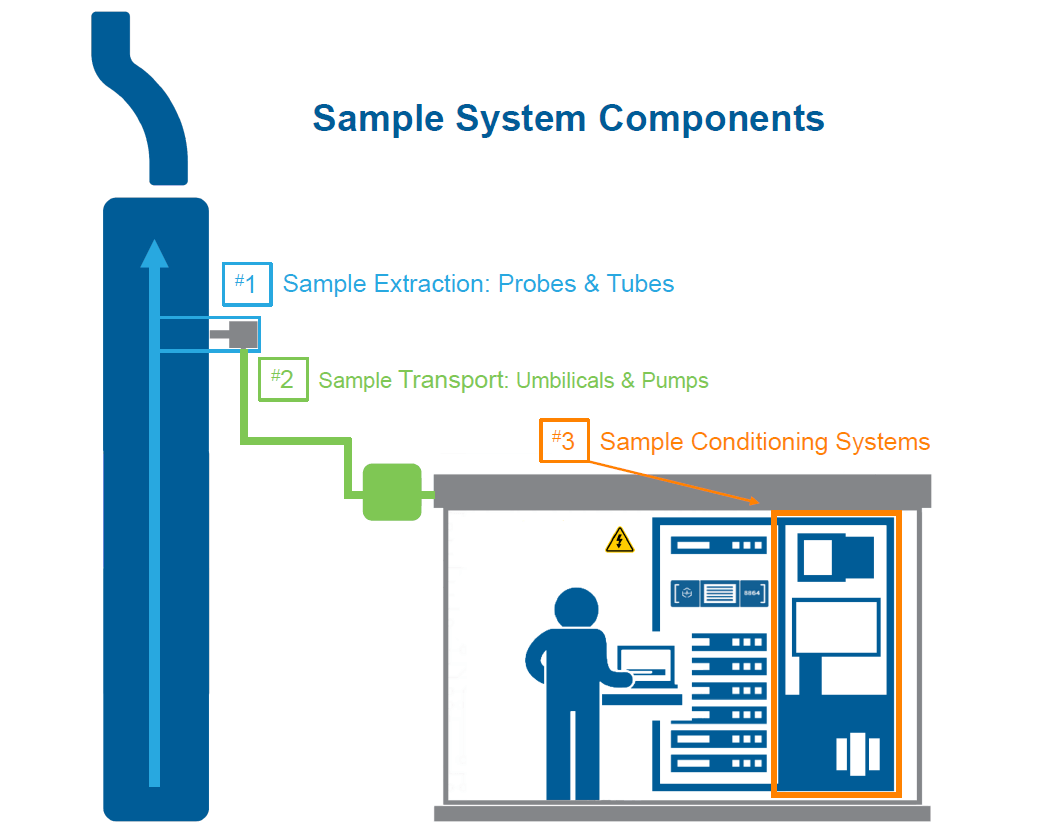

Let’s dive into how a Full-Extractive CEMS is constructed and operated. There are always a few exceptions (like in-situ CEMS), but for the most part, nearly every CEMS manufacturer builds a similar modular system.

These systems start at the stack with a probe. The probe is typically heated and has a filter, and the sample is drawn through it into the umbilical.

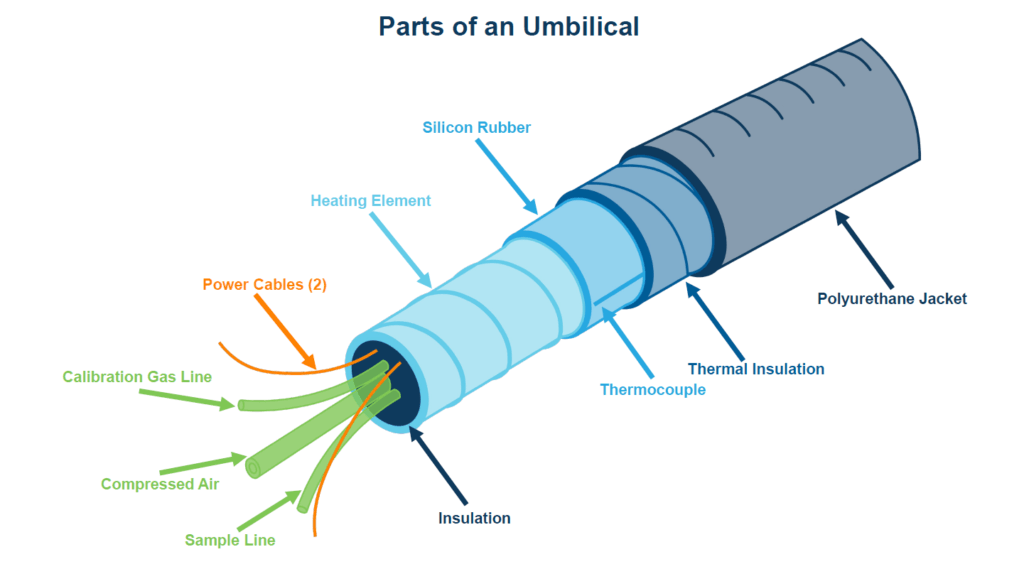

The umbilical carries the sample down the stack to a CEMS shelter or cabinet. It transports calibration gas up to the probe and carries purge air to the probe to clear the lines after.

The sample arrives at the sample conditioner, typically found in the CEMS cabinet/rack or inside the CEMS shelter. The sample conditioner removes the moisture from the sample gas and reduces the temperature to somewhere around ambient, so it’s safe to introduce into the analyzer(s).

The analyzer(s) measures the sample gas for the specific types of gases. Sometimes an analyzer might measure more than one gas. Typically, CEMS analyzers use different measurement technologies for each gas (i.e. NOx is measured with Chemiluminescence technology, Oxygen is measured with Zirconia or Paramagnetic technology, CO, and CO2 with Non-Dispersive Infrared technology). After measurement, the gas is exhausted into the atmosphere.

Along the way, the gas passes through a sample/calibration gas control panel made up of solenoids and rotameters. The calibration gas control panel controls the sample gas and calibration gas flow to the analyzers and probe. Calibration gas bottles are plumbed through the sample/cal control panel to allow for the required calibrations of the CEMS.

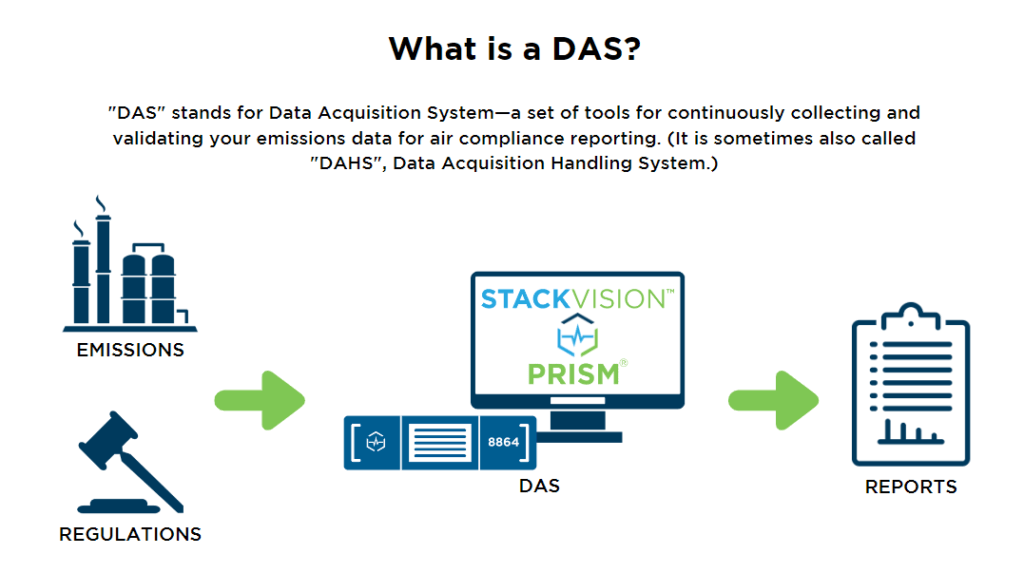

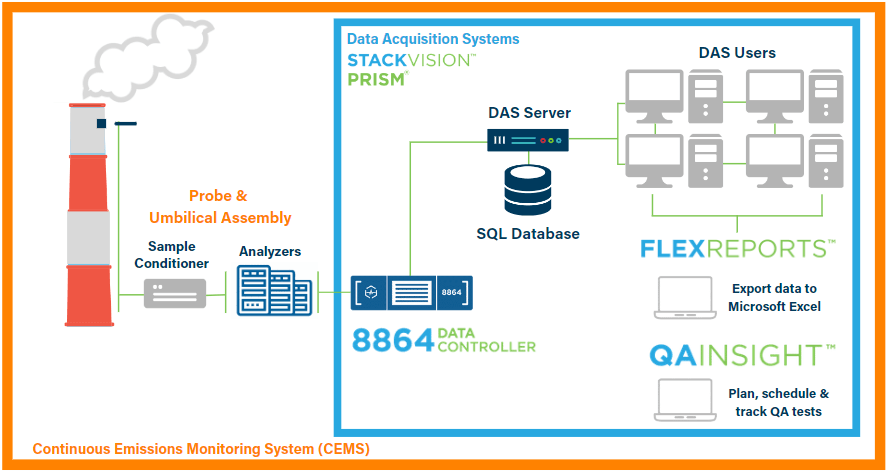

The last component of the CEMS is the Data Acquisition System (DAS). The Data Acquisition System uses a data controller or a PLC to bring data from the analyzers to the DAS server. It collects and stores all the information, perform the emissions calculations, tracks emissions, highlights exceedances, has an alarm system, and more. ESC Spectrum offers StackVision, Prism, & CEMDAS. StackVision and Prism utilize our 8864 Data Contoller while CEMDAS uses a PLC.

There is no single manufacturer for all these parts. For instance, there are three major manufacturers of probes and sample conditioners. There are two major umbilical manufacturers, a plethora of analyzer manufacturers, and several DAS manufacturers (often, the CEMS manufacturer makes their own DAS). Moreover, a probe manufacturer does not make analyzers, and no umbilical manufacturer makes a DAS, etc. Check out the key suppliers we partner with to ensure our customers have access to the right equipment.

If you routinely replace individual components, your CEMS will always be up to date. Check out our CEMS Data Review Checklists to help you ensure your facility is always up to date. Each checklist makes recommendations for Daily and Weekly, Monthly, Quarterly, and Semi-annual/Annual data reviews for your CEM system.

Let’s look a little closer at how easy and cost-effective it is to replace components over the lifetime of a CEMS:

CEM System Probes

In a clean burning process like a natural gas boiler, probes can last upwards of 15-20 years before failing. Because the heater or heater electronics are directly exposed to the unfiltered and hot-wet stack gas, they may fail earlier from corrosion–especially in an excessively corrosive process.

A typical extraction probe cost range is $5,000-$7,500.

Replacement is as simple as disconnecting the umbilical lines and unbolting the probe from the stack port flange. Replacement should take less than four hours.

CEMS Umbilical

An umbilical should last 10-15 years and even beyond. If it’s secured well and doesn’t bounce in the wind, stretch, or get hit by a fork truck or crane, it shouldn’t need much attention over its lifetime. In dirty processes, it may need cleaning from time to time, but that should not affect its lifespan.

The most common failure mechanism after mechanical damage is heater failure. The umbilical will get brittle over time from the sun’s rays. But again, if it’s secured and doesn’t move, it shouldn’t crack or split.

A replacement umbilical costs around $55-$70 per foot. Pricing varies depending on the configuration. Factors that impact the cost of an umbilical include the number of lines, materials used, how many wires, length, etc.

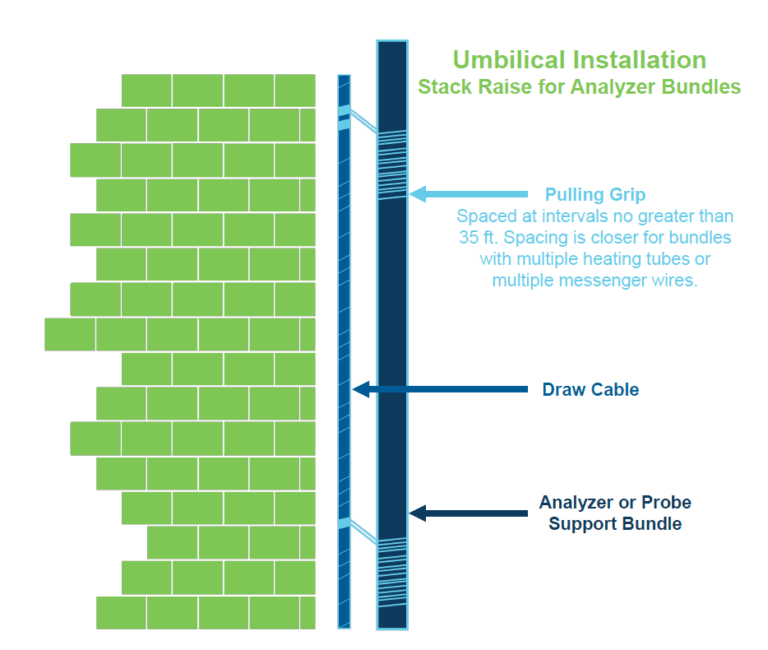

Taking an old umbilical out and putting a new one in can be a big job, depending on how high the stack is and how the umbilical is run. Typically, the existing cable tray is re-used making installation easier the second time.

In most cases, you need to use a crane or lift. The umbilical needs to be handled carefully (lift with support every 10 feet, don’t stretch it, don’t overtighten clamps, etc.). ESC Spectrum is in the best position to help re-terminate the ends at the probe and at the CEMS cabinet or shelter.

Sample Conditioner

A sample conditioner is another component that should last 10-15 years. Of course, this is predicated on good maintenance practices, including proper Preventative Maintenance (PM). Some parts of the sample conditioner, like the sample pump and peristaltic pumps, will be renewed periodically through routine PM.

When sample conditioners fail, it’s usually the electronics of the thermo-electric chiller. Even these parts can be replaced though. Some manufacturers support their units for upwards of 20+ years.

Sample conditioners start at $8,600 and can run upwards of $14,000 for large systems or ones that handle acid gases.

Replacing a sample conditioner is straightforward. The main connections are the sample lines coming in and going out, the power cord, and a signal wire for alarming. Similarly to a probe, a replacement for a sample conditioner can be about a four-hour job.

CEMS Analyzers

With good maintenance and standard repairs, a CEMS analyzer can last 10-15 years and even longer in some cases. Unlike the components above, though, analyzers are something that facilities with CEMS are forced into replacing due to parts being out-of-date and end-of-life support. Most manufacturers offer seven years of support, parts, and repairs beyond the date of the obsolescence announcement.

Most analyzer companies introduce a new model every 10-12 years. If you bought your analyzer eight years into its active lifespan, you might only have 11 years total before it’s no longer supported. If you end up on the wrong end of the life-cycle timing, CEMS companies (not the analyzer manufacturer) still support and repair analyzers past seven years as long as they can still get parts. Thankfully, parts are often interchangeable across old and new models.

Of course, there are plenty of other ways analyzers can fail. But if the necessary parts are still available, they can be repaired and rebuilt. Sometimes it can be more cost-effective to replace an analyzer rather than repair it. Read more CEMS Analyzers: What They Are & How To Maintain Them.

Single gas analyzers vary in cost depending on the gas. The price range is typically somewhere between $12,000 & $22,000 for the most common gases (NOx, CO, CO2, THC & SO2). You can replace a typical analyzer in less than an hour.

Sample/Calibration Control Panel

Sample/Calibration panels come in two typical varieties. First, you have a 19” rack-mounted “case” with all the components inside it. The more common option is a front plate with the rotameters and gauges connected to a slide-out shelf with the solenoids and other components mounted behind.

The first type typically has more electronics built into it and can fail to the point of needing replacement. It’s unlikely that you’ll need to replace the second type. You can replace rotameters, solenoids, and gauges intermittently over the life of the Continuous Emission Monitoring System as needed.

Choosing a Data Acquisition System (DAS) For Your Facility

The Data Acquisition System is a commonly replaced component of a CEMS. There are various reasons why you might replace a DAS system. Some customers will even switch a DAS due to preference or frustration with the company. Data Acquisition Systems are used for accurate and reliable air emissions monitoring and reporting to meet the EPA’s regulations including state and local requirements.

The DAS is most commonly made up of two components– the Data Logger (or PLC) and the server (or PC). Replacing a DAS is complicated, and a user can’t do this on their own. A lot of programming and configuration work goes into making sure everything works with the CEMS and all the other components. Data Acquisition Systems like ESC Spectrum’s StackVision and Prism are increasingly becoming necessary for facilities to meet compliance as rules and regulations evolve. Our experts are standing by and readily available to help implement a DAS at your facility for easy monitoring and reporting of air emissions. Contact us today for a demo. Are you at the step of already implementing a DAS? Read why it’s important to never skip the Factory Acceptance Test.

Does a CEMS Require New Certification With New Installation of a Component?

One important thing to keep in mind with any Continuous Emission Monitoring System upgrade is the potential requirement for a new certification test. A CEMS is certified as a combination of all its components. When a component is changed out, the entire CEMS must be re-certified. That applies to probes, umbilicals, sample conditioners, and analyzers.

Overall…

The great thing about owning a modularly built CEMS is that the large initial cost outlay should only happen once. With proper planning through the years, you can maintain a state-of-the-art CEMS with “current” components for a lifetime. Yes, those components still cost a pretty penny, but they can be budgeted. You spend a little every year versus one big major cost. And most of those costs shouldn’t start until 10 years into the life of your CEMS.

ESC Spectrum's CEMS Overview

ESC Spectrum Recommendations to Ensure an Optimized CEMS:

Our CEMS Services department provides customizable maintenance contracts to meet your specific needs, ranging from periodic visits and on-site assistance or training to employees to full turnkey solutions including all labor, parts and response, and uptime guarantees. Request a Site Walk today and we’ll send someone out to review your facility’s CEM System to make recommendations for Preventative Maintenance (PM).

Consider hiring a part-time CEMS Tech if you are operating more than 6 CEMS at your facility. A highly skilled CEMS tech, dedicated to CEMS only, can maintain 10+ CEMS (at HRSG or CT plants). It will likely take a new I&C tech 1-2 years to become comfortable with CEMS functionality and behaviors.

Consider hiring a CEMS Service contractor for the first year of operation for on-the-job training.

ESC Spectrum’s 4-Step Umbilical Inspection and Installation service help you keep your facility healthy to avoid downtime and failures.

We offer customized solutions that include parts from major emission monitoring manufacturers and the expertise needed to repair, maintain, and upgrade your CEMS analyzers.

ESC Spectrum offers 24/7/365 best-in-class customer support from a dedicated team of experts, services, and online and in-person training for our customers. Our products are always in continuous development to keep pace with industry changes. Contact us for a quote today to learn which DAS is right for your facility.