What is a CEMS Analyzer?

Continuous Emissions Monitoring Systems (CEMS) consist of a series of gas analyzers for monitoring various air pollutants. Analyzers are integral to your CEMS as they measure gases, including NOx, SO2, CO, CO2, O2, THC, NH3, and more.

CEMS Analyzers can apply two processes, Straight-Extractive CEMS, and Dilution CEMS.

CEMS Analyzers also use different technologies for different gasses, such as Chemiluminescence, Pulsed Fluorescence, NDIR (Non-dispersive Infrared Sensor), FTIR (Fourier-transform Infrared Spectroscopy), FID (Flame Ionization Detector), and Zirconium Oxide. Through a long history of experience, certain analyzers are suited best for specific gases. For example, Pulsed Fluorescence offers the best sensitivity for low range Sulfur Dioxide (SO2) measurement, while Chemiluminescence is best for low range Nitric oxide (NOx) measurement.

Manufacturing Practices for Analyzers

Analyzers last around 15 years or more, and their lifespan is dictated by the manufacturer’s ability to continue to support them.

Often, the decrease in the availability of parts ceases the manufacturers’ ability to support while some manufacturers continuously make upgrades to their analyzers and will discontinue support after the new CEMS analyzers come to market. This could potentially be as short as seven years.

Other CEMS manufacturers will continue to support analyzers as long as possible.

CEMS Analyzer Maintenance

As your facility’s continuous emissions monitoring systems age, it’s vital to keep up with CEMS analyzers to avoid the potential risk of downtime and avoid its fading reliability. This is especially true for analyzers that are no longer receiving support from manufacturers.

Preventative Maintenance is recommended quarterly with analyzers while other PM tasks are done annually. It’s important to keep up with their lifecycle to maintain air emissions monitoring requirements. Read more about determining where your facility’s analyzer’s lifecycle is at.

This video discusses the Theory of Operation, identifying the basic layout of the analyzer including the external and internal components and the tools to perform recommended preventative maintenance for the Thermo Fisher Scientific NOx Analyzer. This video goes over the recommended maintenance actions including a Fan Filter and Capillary inspection and replacement.

ESC Spectrum’s Analyzer Resources

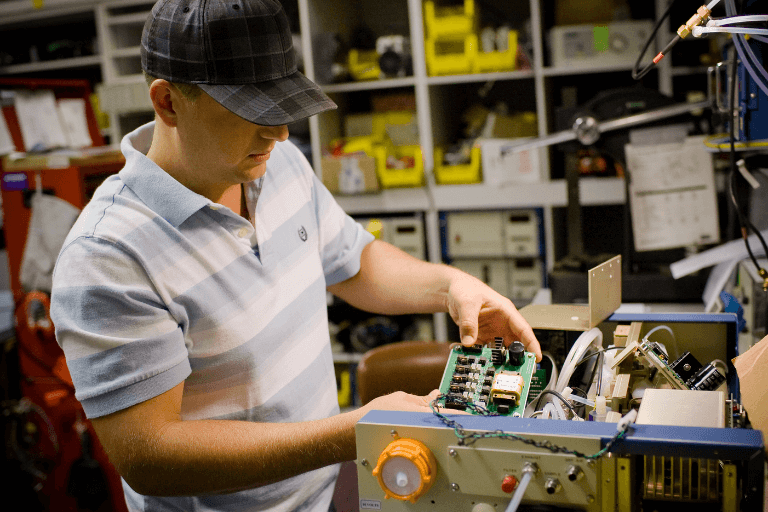

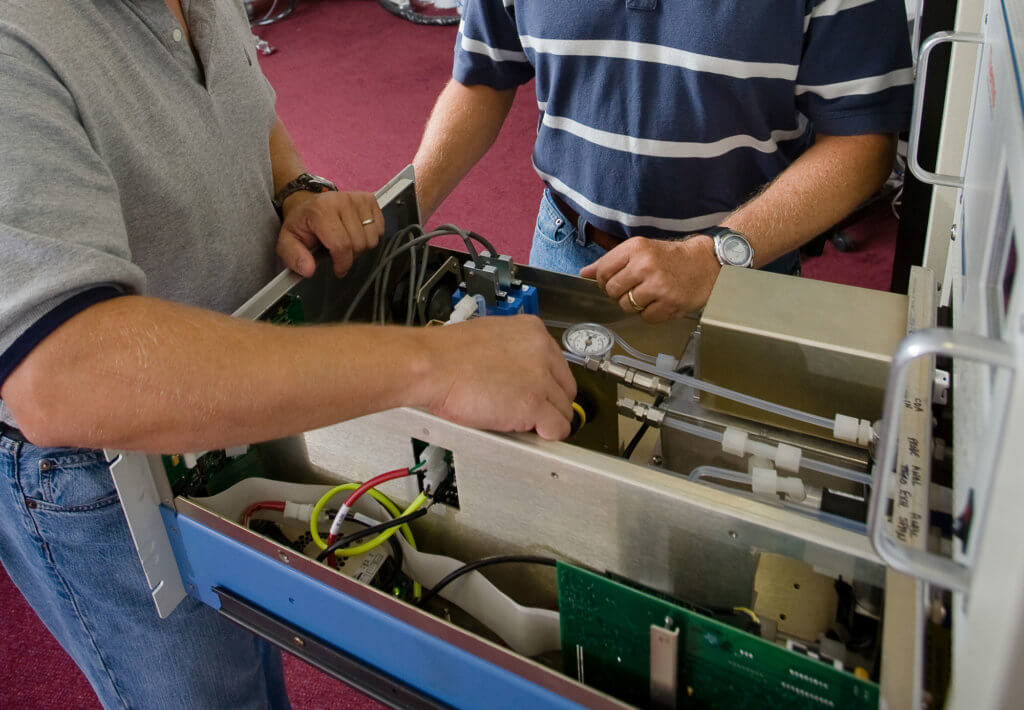

At ESC Spectrum, we can help you determine when it’s time for a repair to your CEMS analyzer or a replacement for a new one. We also offer other analyzer services including calibration and upgrades.

We operate multiple full depot-level labs with the ability to repair and refurbish most major CEMS analyzers. We offer loaner and rental analyzers during repair to help your facility stay in compliance with air emissions monitoring regulations.

Eventually the cost of repairs and potential risk of downtown becomes too great, demanding the purchase of replacement analyzers. We can help pick out the analyzer that best fits your application.

We perform Elemental Mercury Calibrator certifications in accordance with the Interim EPA Traceability Protocol as well as Neutral Density Filter certifications as required by the EPA’s Part 60 regulations.

Our Calibrator Certification Service compares and tests the Thermo Hg 81i Mercury Calibrator against a NIST traceable vendor prime. Our lab is the only facility beside the manufacturer certified to repair and calibrate these devices.

We help with the installation of analyzers from the following CEMS manufacturers:

ESC Spectrum also offers our CEMS Protect Program which provides services you need to protect your equipment, including analyzers, and stay in compliance. We work with technicians to complete all required quarterly maintenance and activities and provide on-the-job training and support.

Send us a list of your analyzers and we’ll provide a quote for spares and/or replacements. We have agreements with suppliers that ensure timely delivery service. Fill out this form to upload your list and we’ll reach out as soon as possible.

Interested in learning a more comprehensive overview of how CEM Systems work? Read Understanding Continuous Emissions Monitoring Systems (CEMS): A Comprehensive Guide. This guide will give you a complete understanding of all the components in the flow of a CEMS.

Taylor Hempel - Marketing Specialist II

Taylor Hempel is a skilled marketer specializing in content creation, social media management, and driving customer engagement. With a BBA in Marketing from the University of Texas at San Antonio, she joined ESC Spectrum in February 2022. Taylor is adept at crafting informative content about continuous emissions monitoring systems, its components and data acquisition systems allowing her to craft content that educates and informs industry professionals.