In the refining industry, controlling air emissions is crucial for maintaining environmental compliance and protecting public health. Refineries, which handle volatile organic compounds (VOCs) and hazardous air pollutants (HAPs), often rely on thermal oxidizers as an effective pollution control solution.

This blog explores how thermal oxidizers work, common technologies used in refineries, and how data acquisition software helps comply with the regulatory framework set by the Environmental Protection Agency (EPA).

What Are Thermal Oxidizers?

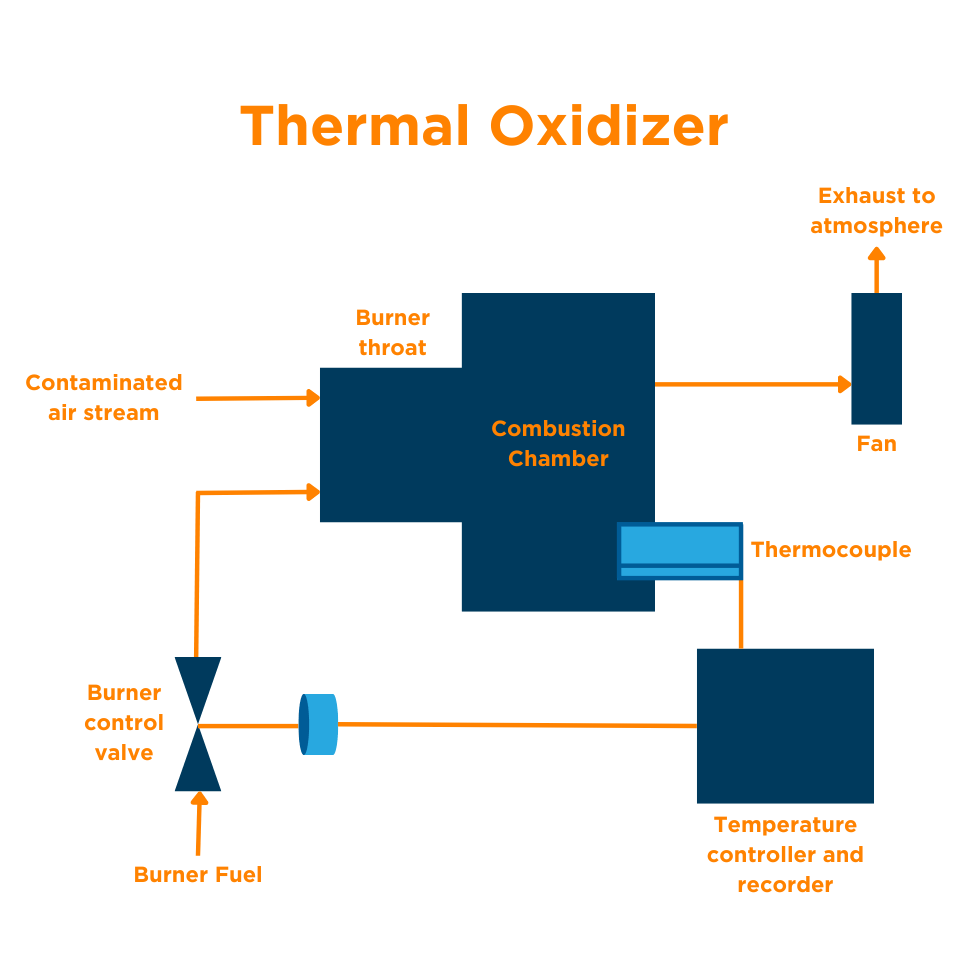

1. High-Temperature Combustion:

The polluted airstream is introduced into a combustion chamber where it’s exposed to temperatures ranging from 1,200°F to 1,800°F, causing the organic compounds to oxidize.

2. Adequate Residence Time:

The air is held at these elevated temperatures long enough to ensure complete breakdown of the VOCs and HAPs.

3. Sufficient Oxygen:

Oxygen is supplied to facilitate efficient oxidation.

4. Clean Exhaust:

The result is a cleaner exhaust with significantly reduced levels of harmful compounds, primarily CO₂ and water vapor.

There are various types of thermal oxidizers, however refineries typically use two types:

- Regenerative: Use heat recovery to destroy pollutants by oxidizing them at high temperatures (usually between 800°C and 1,100°C).

- Recuperative: Use heat exchangers to preheat the incoming waste stream, reducing the energy required for oxidation. Better for smaller systems with low energy requirements.

Principle of a Basic TO Technology

Thermal Oxidizers and Data Acquisition Systems: An Integrated Relationship in Refining

While thermal oxidizers are key to destroying pollutants before they are released into the atmosphere, Data Acquisition Systems (DAS) play an equally important role in ensuring that emissions data is collected, stored, and reported accurately. In the refining industry, where precise data is necessary to demonstrate regulatory compliance, a DAS enables operators to track and manage emissions effectively.

To learn more on Data Acquisition System’s and their use in refineries, read our blog post on the topic.

EPA Regulations Involving Thermal Oxidizers in Refineries

The EPA enforces strict regulations on refinery emissions, with thermal oxidizers playing a key role in compliance. The following regulations are particularly relevant:

1. Clean Air Act (CAA):

The CAA mandates refineries to limit emissions of VOCs, HAPs, and other pollutants. Thermal oxidizers are commonly used to keep emissions below permitted thresholds, especially under Title V, which requires operating permits for facilities exceeding specific emission limits.

2. National Emission Standards for Hazardous Air Pollutants (NESHAP):

NESHAP targets pollutants from refineries such as benzene and formaldehyde. Thermal oxidizers are often employed to meet the stringent emission reductions required by NESHAP standards.

3. New Source Performance Standards (NSPS):

Refineries must adhere to NSPS, which set limits for new or modified sources of pollution. The installation of thermal oxidizers is frequently required to meet these standards.

4. Maximum Achievable Control Technology (MACT):

MACT standards require refineries to implement the best technology available for controlling HAP emissions. Thermal oxidizers are considered a MACT solution due to their high efficiency in pollutant destruction.

How ESC Spectrum Can Help With Thermal Oxidizers

At ESC Spectrum, we specialize in Data Acquisition Systems such as StackVision that integrate seamlessly with pollution control devices like thermal oxidizers. Our software monitors operating parameters for TOs to help demonstrate compliance. We can help configure different systems within your facility to measure parameters within StackVision.

StackVision’s customization options allow refineries to tailor the data collection and reporting process to suit the specific needs of each site, ensuring regulatory compliance while streamlining operations.

Contact us today to learn how our DAS solutions can support your refinery’s environmental goals.

For a complete resource on emissions monitoring, explore our Comprehensive Emissions Monitoring Guide for Refining and Petrochemical Facilities, covering everything from best practices to regulatory compliance.

Dan Napolitan - Marketing Specialist I

Dan joined ESC Spectrum in August of 2023 as a Marketing Specialist I. He started this position shortly after graduating from the University of Missouri with a degree in Journalism and Strategic Communications. Prior to working with ESC Spectrum, Daniel gained experience in the digital marketing field doing SEO and keyword research to produce successful organic content. He is now responsible for completing various marketing tasks such as blog writing, social media posts, paid search advertisements, web analytics, and more.

Contact Dan at dnapolitan@escspectrum.com for questions or comments.