The Importance of Staged Flares and Valve Positioning in Refining Processes

This blog explores the critical role of staged flares and valve positioning in refining operations, highlighting their impact on emissions monitoring, compliance with EPA regulations, and overall operational efficiency through the use of StackVision DAS.

Understanding Thermal Oxidizers and Their Role in Emission Control: Key Insights for the Refining Industry

Learn how thermal oxidizers operate alongside data acquisition systems to ensure EPA compliance and accurate data collection in refineries.

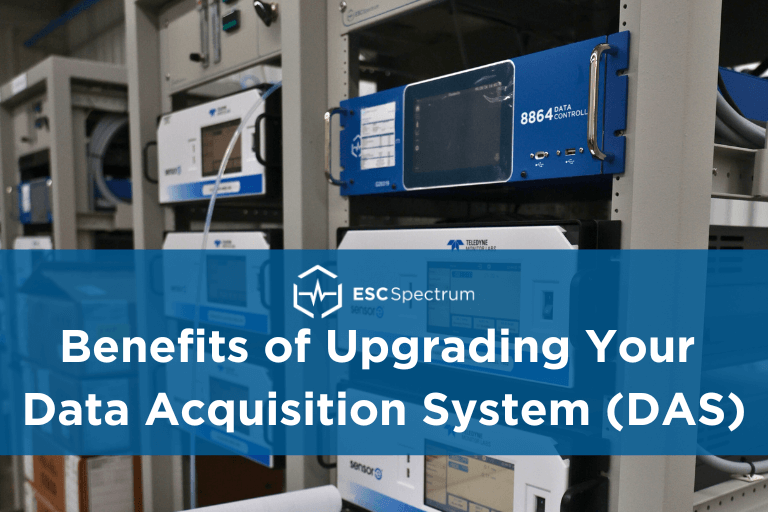

Benefits of Upgrading Your Data Acquisition System (DAS)

In today’s regulatory landscape, ensuring air emissions compliance is crucial. A reliable and robust Data Acquisition System (DAS) plays a pivotal role a Continuous Emissions Monitoring Systems (CEMS). Upgrading your DAS offers numerous benefits, read more to explore the advantages of upgrading and what you can expect from the DAS changeout process.

New Release: Prism Version 2.0 Data Acquisition System

We’re excited to announce the release of Prism Version 2.0! This release provides new features designed to make CEMS compliance and monitoring easier and more productive than ever.

Data Acquisition in Refineries: Plant Process Systems vs Data Controllers

This blog post will walk you through all the ways using the 8864 Data Controller in refineries can mitigate risks for your facility.

Improving Operational Efficiency with Data Acquisition Systems in Refineries

This blog post will walk you through all the ways having a Data Acquisition System for refineries can improve overall operations and efficiency.

Using a Data Acquisition System for Greenhouse Gas (GHG) Emissions Compliance

Learn more about Greenhouse Gas (GHG) emissions and how using a Data Acquisition System can help you stay in compliance.

An Inside Look at Ethanol Regulations in the CEMS World

The 2007 EPA 40 CFR Part 60 permits’ rule about chemical process plants changed ethanol regulations for CEMS. After 15 years since this rule change, it could be time to update your ethanol plant’s emission monitoring system and possibly look for a DAS that helps comply with 40 CFR Part 60 regulations.

Don’t Skip The Factory Acceptance Test (FAT)

The purpose of a FAT is to verify that equipment/software for a new project is working properly prior to installation. While FATs are not required, they are certainly a very important step in ensuring a successful project.

Reporting Month: Key Air Compliance Lessons Learned

Once the fourth quarter’s reporting window has closed, there is finally an opportunity to reflect on the past year. We compiled a list of air compliance lessons learned, based on customers’ feedback.

RATA Load Analysis Errors and How to Avoid Them

Load Analysis Errors are usually discovered after a RATA test has been conducted and can lead to hundreds of hours of invalid data. To avoid this error at your facility, learn about some of our best practices to consider when planning your next RATA test.

New Firmware Release Further Enhances the Robust and Reliable 8864 Data Controller

The 8864 Data Controller Firmware v6.02.r60 includes a number of new features that enhance its usability and reliability.