Downtime due to Continuous Emissions Monitoring System (CEMS) hardware can lead to compliance risks, operational inefficiencies, and costly repairs. A solid approach to maintenance, calibration, system upgrades, and spare parts management is key to keeping your system running smoothly. Below are some key strategies to help navigate CEMS maintenance and perform it at the best possible times.

Potential CEMS Downtime Causes

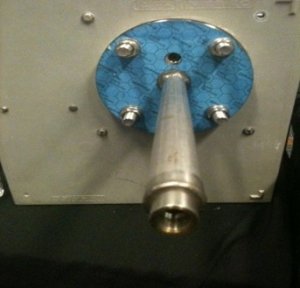

Prefilters & Stingers

Issues with prefilters and stingers can lead to inaccurate readings and system downtime if not properly maintained. Common problems include:

- Holes in stingers: These can allow outside air to enter the sample stream, leading to incorrect data readings.

- Plugged flanges: Blockages restrict sample flow, reducing system efficiency and causing potential compliance issues.

- Leaking gaskets: Air leaks can introduce external air or cause pressure imbalances, affecting emissions data accuracy.

Umbilicals

Umbilicals are essential for maintaining the integrity of sample transport, but they can develop issues that lead to downtime. Common problems include:

Leaks: Cracks or loose connections in the umbilical lines can allow sample loss or the introduction of outside air, leading to inaccurate readings and regulatory compliance issues.

Heater problems: Malfunctioning or insufficient heating can cause condensation buildup, which affects sample integrity and may lead to system failure.

Contamination: Over time, umbilicals can accumulate particulate matter or chemical residue, restricting sample flow and affecting measurement accuracy.

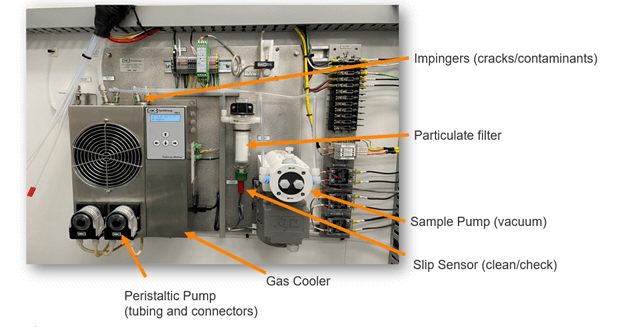

Sample Conditioning Systems

Sample conditioning systems ensure the quality and reliability of emissions data, but issues with key components can lead to downtime. Common problems include:

Pumps: Malfunctioning or clogged pumps can disrupt sample flow, leading to inaccurate readings or complete system failure. Regular inspections and timely replacements help prevent unexpected breakdowns.

Filters: Dirty or clogged filters can restrict airflow and contaminate samples. Routine filter changes are essential to maintaining consistent system performance.

Slip sensors: These sensors protect the system by shutting down pumps when moisture is detected. If a slip sensor is faulty or improperly maintained, it may either cause unnecessary shutdowns or fail to prevent water-related damage.

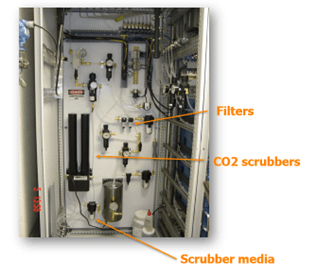

Air Cleanup Systems

Air cleanup systems play a critical role in maintaining accurate emissions measurements by ensuring clean, dry instrument air. Common issues that can lead to downtime include:

Filters: Clogged or degraded filters can allow contaminants to pass through, affecting the accuracy of analyzers and causing potential damage to sensitive components.

Scrubber media: Over time, scrubber media becomes saturated and loses effectiveness, allowing unwanted gases to remain in the instrument air supply.

CO₂ scrubbers: A failing CO₂ scrubber can introduce bias into emissions measurements by not properly removing CO₂ from the instrument air, leading to incorrect dilution calculations.

N₂ generators: Malfunctioning nitrogen generators can result in inconsistent or insufficient nitrogen supply, which is crucial for proper calibration and zero gas generation.

Analyzers and Monitors

Analyzers and monitors are critical components of a CEMS, and various issues can lead to downtime. Regular inspection and maintenance of key components help ensure accurate readings and system reliability. After any repair or maintenance, a Hands-Off Calibration must be performed to verify proper operation. The following is a list of some components to keep an eye on when maintaining different types of analyzers:

NOx Analyzers: To ensure accurate readings, the ammonia scrubber, critical orifice O-rings, reaction chamber, convertor, PMT voltage, permeation dryer, silica scrubber, ozone destroyer, and pump must be monitored.

SO₂ Analyzers: Require regular maintenance of the reaction chamber, mirror assembly, PMT voltage, hydrocarbon kicker, and pump.

CO and CO₂ Analyzers: Optical bench, mirrors, IR source, S/R or M/R ratio, and Pump

Flow Measurement Systems: To ensure proper function, clean ports, transducers or pitot tubes, purge motors, and purge filters.

Opacity Monitors: Clean ports, clean lenses, purge motors, and purge filters

Data Controllers

The 8864 Data Controller is a vital component of a CEMS, ensuring accurate data acquisition and processing. Keeping its firmware updated provides critical security updates, bug fixes, and new features that enhance system reliability. If the controller nears the end of its service life, replacing it is essential to avoid compatibility issues, security vulnerabilities, and unavailable replacement parts.

Upgrading the 8864 Data Controller improves processing speed, expands storage capacity, and enhances dashboard functionality. These upgrades lead to better data accuracy and ultimately reduce downtime. Regular maintenance, including checking power supplies and connections, further ensures optimal performance and longevity.

Visit our 8864 Data Controller page to learn more today.

Additional CEMS Downtime Resources

Reducing downtime in your CEMS requires consistent maintenance, proper calibration, timely upgrades, and a well-managed spare parts inventory. By following these steps, facilities can maintain compliance, prevent system failures, and keep operations running efficiently.

ESC Spectrum provides CEMS solutions, maintenance services, and expert support to help you manage your emissions monitoring system. Contact us today to learn how we can help keep your facility running smoothly.

Want to learn more about CEMS parts and maintenance? Enroll in our online CEMS training courses or read “Understanding Continuous Emissions Monitoring Systems (CEMS): A Comprehensive Guide.”

John Cutaia - Field Service Technician V

John has been in the industry for over 32 years, starting with stack testing in 1992. He comes from Luminant Power where he was in the CEMS support group for 10 years, providing support to all power plants on continuous emission monitoring system hardware and software. John also was a training instructor for Extractive and Dilution (CEMS) systems for plant site technicians.

Daniel Napolitan - Marketing Specialist I

Daniel joined ESC Spectrum in August of 2023 as a Marketing Specialist I. He started this position shortly after graduating from the University of Missouri with a degree in Journalism and Strategic Communications. Prior to working with ESC Spectrum, Daniel gained experience in the digital marketing field doing SEO and keyword research to produce successful organic content. He is now responsible for completing various marketing tasks such as blog writing, social media posts, paid search advertisements, web analytics, and more.

Contact Daniel at dnapolitan@escspectrum.com for questions or comments.