Air, Dust, and Tunnel Monitoring

ESC Spectrum offers a full range of Air, Dust, and Tunnel Monitoring Systems to ensure highly reliable monitors for your Continuous Emissions Monitoring Systems (CEMS). Our 30+ years of expertise in process and environmental monitoring and reporting are ideal for meeting the requirements of installing air, dust, and tunnel monitoring for your facility’s CEM System. We partner with a wide range of suppliers to provide you with high-quality products, including the options below.

Tunnel Monitoring

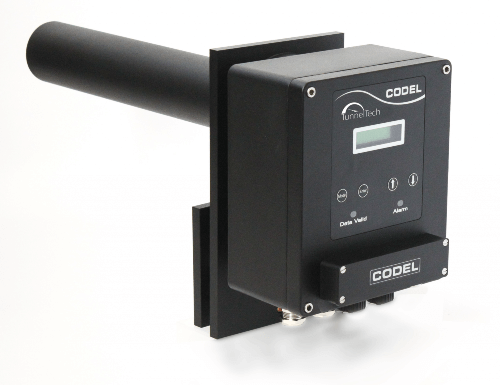

CODEL TunnelTech 700 Series EC Tunnel Monitoring

Product Applications:

-

Road Tunnels

-

Rail Tunnels

Features:

-

Measure CO, NO, NO2 & Visibility in one compact sensor

-

Advanced electrochemical cell technology

-

High resolution measurement

-

Minimal maintenance requirements

-

Available in 316 Stainless Steel

Monitors the atmosphere within the tunnel and ensures that the tunnel ventilation system provides sufficient clean air to protect tunnel users’ health and for drivers to see the road ahead clearly.

To measure visibility levels, the TunnelTech 700 Tunnel Monitoring Analyzer uses electrochemical cell technology to determine CO, NO & NO2 concentrations and optical attenuation.

As there are no moving parts, reliability levels are very high, and maintenance requirements are low.

Visibility sight tubes are utilized to ensure that airborne dust and contaminants do not reach the optical windows and cause drift.

CODEL TunnelTech 600 Series EC Monitor

Product Applications:

-

Road Tunnels

-

Rail Tunnels

Features:

-

Metal/glass encased silicon photodiode, Vl filtered to human spectral response

-

Accuracy +/-1%

-

Measurement of tunnel entrance luminance - 0 - 6,500 cd/m2

-

Perfectly linear within its measuring range and has an instantaneous response to changing light levels

Monitors the average luminance of a tunnel entrance and its surroundings.

In accordance with Commission Internationale de l´Eclairage, (C.I.E.), publication 88, 1990 recommendations, the photometer monitors the average luminance within a 20-degree angle over a standard range of 0 – 6,500 cd/m2.

According to CIE recommendations, luminance should be monitored as the luminance contained within in a conical field of view, subtending an angle of 20º.

It is recommended that the luminance photometer is mounted in the tunnel approach road approximately 120 – 200 meters from the portal,

depending on the approach speed of the vehicles and their stopping distance.

Air Monitoring

CODEL TunnelTech 100 Series Air Quality Monitors

Product Applications:

-

Road Tunnels

-

Rail Tunnels

Features:

-

Continuous measurement of visibility in road and rail tunnels

-

Optional, integral ambient temperature measurement for locating fires

-

No moving components providing maintenance-free operation

-

PC-based software for commissioning and maintenance

-

Accurate optical attenuation technology

-

Optional Modbus RTU serial outputs

-

Analogue 4-20mA output

Used in combination with other TunnelTech 101 VIS monitors, the operator can quickly detect the focus of the fire if it is also equipped with the optional PT100 temperature sensor to accurately measure ambient air temperature in a range of -15 to 1050C.

Fully configurable analog and alarm outputs are exportable to the tunnel data acquisition system to provide real-time visibility data. This data is also exported via the RS 485 serial port along with the temperature data.

This link delivers MODBUS RTU encoded data to a SCADA system located in the tunnel control center and/or a local display module.

In addition, the IP65-rated enclosure is coated to resist attack from aggressive gases and road salt and to resist the effects of extreme heat.

Optional transmitter and receiver insulation jackets are available to reduce the effect of extremely low temperatures.

Another option is a local display, driven from the RS485 output, which enables operators to view output data, diagnostics, and alarm setpoints.

CODEL TunnelTech 200 Series Air Quality Monitors

Product Applications:

-

Road Tunnels

-

Rail Tunnels

Features:

-

Continuous measurement of visibility in road and rail tunnels

-

Precision transmissometer that measures the attenuation of UV and blue light by NO2

-

Class-leading Accuracy, repeatability, and resolution

-

Rugged, corrosion-resistant construction

-

Minimal maintenance requirements

-

Optional RS 485 (Modbus) Output

-

One moving part means high reliability

Use well-proven infra-red techniques to determine CO and NO concentrations and optical attenuation to monitor Visibility levels.

Fully configurable analog and alarm outputs are exportable to the tunnel data acquisition system to provide real-time CO, NO, and Visibility data.

The light source is a near-infrared LED where the interfering effects of particulate in the atmosphere are eliminated by making the measurement within a meter-long diffusion cell into which the atmospheric gases, but not the particulate, can freely diffuse.

The optic surfaces remain clean because they are contained within the diffusion cell, preventing dirt deposition on them. The filters through which the gas diffuses do not become blocked because the diffusion process exerts no force on particulate to force them into the filter pores.

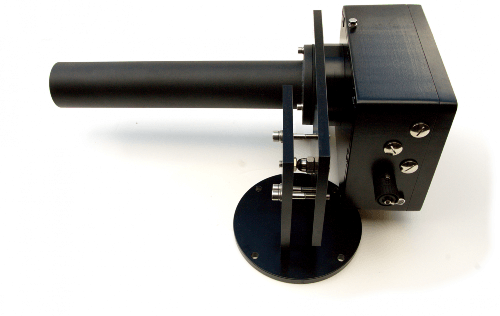

CODEL TunnelTech 305 Air Flow Monitor

Product Applications:

-

Road Tunnels

-

Rail Tunnels

Features:

-

Single point altrasonic measurement technology

-

Unaffected by traffic flow and sound reflections

-

No moving components providing maintenance-free operation

-

Designed to withstand the harshest of tunnel environments

-

Measurement precision of =/- 0.1m/sec

-

Easy mounting system

Monitors both the airflow and the direction of airflow inside a tunnel.

It has no moving parts, which ensures high reliability and minimal maintenance.

The sensor is constructed using stainless steel for ultimate protection against the harsh environments found in tunnels.

Fully configurable 4-20mA analog outputs are provided along with digital alarm outputs.

An RS485 output is also available, allowing data delivery via MODBUS protocol to a SCADA system located in a tunnel control center.

Dust Monitoring

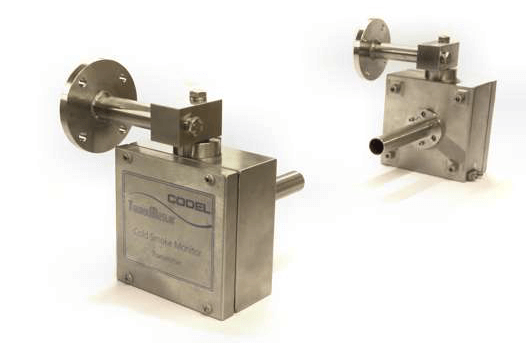

CODEL EnergyTech 301 Triboelectric Dust Monitoring

Product Applications:

-

Coal and Fuel-oil Fired

-

Wood-fired

-

Converter Plants

-

Pulp and Paper

-

Processing

-

Asphalt and Cement

Features:

-

Minimal maintenance requirements

-

Low installation costs

-

No critical alignment

-

No optical surfaces to keep clean

-

Easy to install

Uses well-proven triboelectric sensor technology to directly measure mass particulate concentration by sensing the frictional charge created when particles collide with a conductor.

The advanced electronics of the EnergyTech 301 Tribo Electric Dust Monitoring system detect this signal and present it to the operator via RS485 or 4-20mA directly from the sensor head.

The EnergyTech 301 also features a built-in display for viewing live sensor data as well as for configuration and calibration. An integrated calibration function can correct the measurement levels to mg/m3.

The triboelectric technique is extremely sensitive and capable of detecting dust concentrations of less than 1mg/m3 in small ducts.

Michael is always very professional and knowledgeable.

I am always confident things will be resolved quickly with him.

Dave Patterson

Consulting Engineer (Air Quality Group), Ameren

ESC Spectrum has provided excellent engineering and procurement support.

Juan Cantu

Analyzer Specialist, ENglobal

Alex was very helpful in resolving the issues that I brought to him.

Kevin Bugay

Process Engineer, Cardinal Corporation

Even though we are only data logger users, the support staff has always been extremely nice,

very timely and completely knowledgeable on the topic at hand.

John Markely

Sr. Environmental Engineer, Kyger Creek

Very helpful, understood my issue and found the fix I needed.

Dane Ruberg

Instrument Technician, Xcel Energy

Scott is fantastic, very knowledgeable and very helpful!

Always know I am going to get the help I need when he answers the phone.

Celena Arreola

Environmental Engineer, El Paso Electric

Outstanding customer service!!!

Rick Gregory

IT Specialist/Network Admin, Calumet Specialty Partners

The customer service provided was quick and the agent sent additional information.

Ann Woods

Environmental Scientist, Agua Fria Generating Station

Excellent work!

Daniel Fefer

Contractor, Exelon

Case Studies

StackVision™ Case Study: Calumet Refinery

Learn how Calumet refinery used the StackVision DAS for flare monitoring and compliance with the Refinery Sector Rule (RSR).

StackVision™ Case Study: Pfizer Groton

Learn how the StackVision data acquisition system (DAS) helped Pfizer Groton comply with air regulations more efficiently.

StackVision™ Case Study: Delek-Tyler Refinery

Learn how the Delek-Tyler, TX refinery employed the StackVision Data Acquisition System to solve their complex needs and comply with RSR regulations.