What is the Refinery Sector Rule (RSR)?

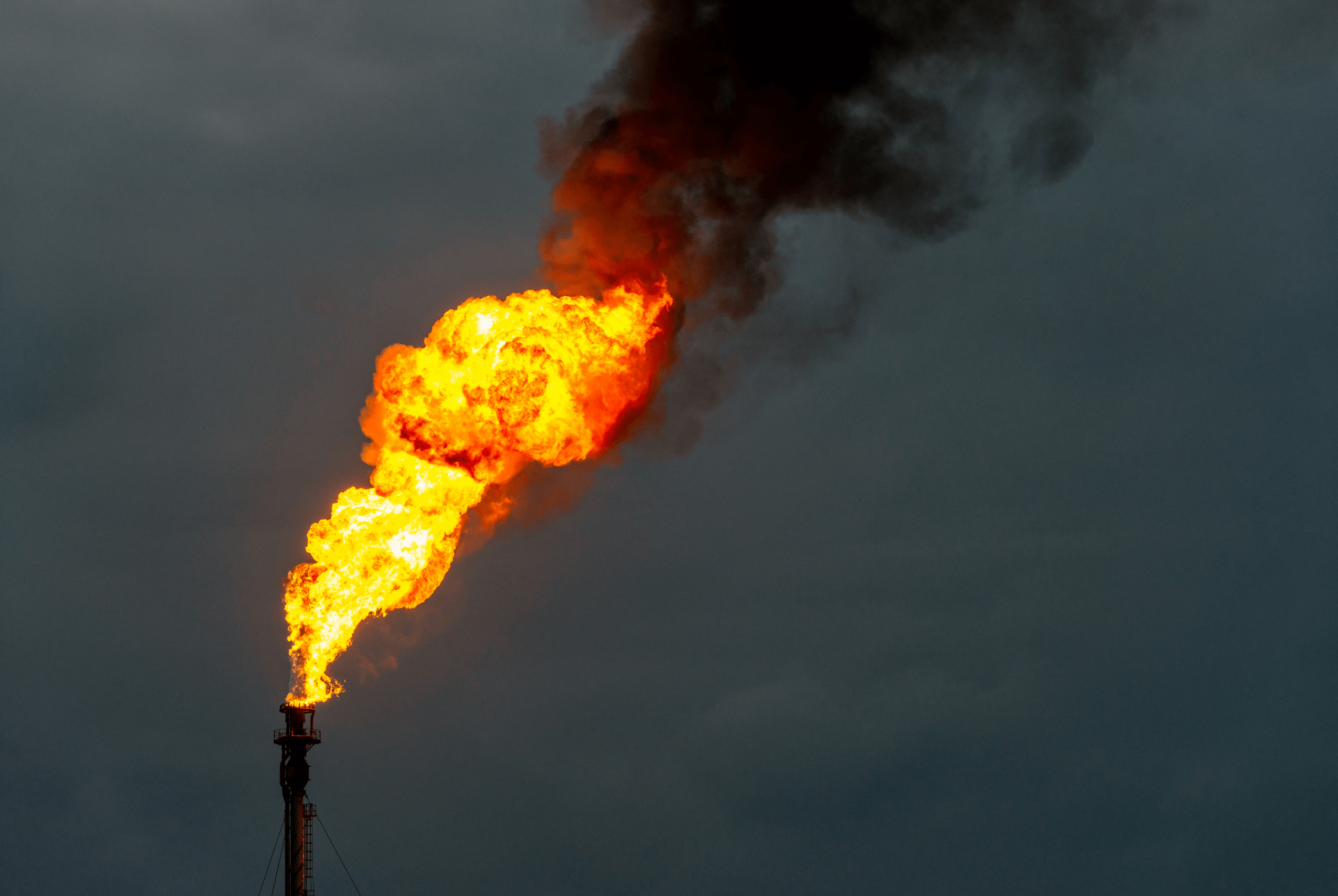

The Environmental Protection Agency (EPA) 40 CFR Part 63 Subpart CC (MACT CC) requirements via the Refinery Sector Rule (RSR) mandates refineries make flare minimization a priority. Additionally, it requires refineries to monitor and report when regulated material does flow to the flare and the destruction and removal efficiency (DRE) at which the elevated flares operate (96.5% combustion or 98% DRE).

RSR also requires active monitoring and immediate response to maintain minimum efficiencies, on average quadrupling the amount of required data to be collected and reported. Making the necessary monitoring improvements to comply with RSR is operation, employee, and data-intensive.

What Challenges Are Posed by the Refinery Sector Rule?

The following RSR requirements are difficult to meet if you are not using a data acquisition system (DAS) like StackVision:

15-minute block averages and complete documentation of algorithms for compliance

Increased quality control (QC) activities and associated recordkeeping

Ready access to compliance parameters for operators

The requirement to retain and make available extensive supporting data along with reporting deviations

Emergency flaring limits without startup, shutdown, and malfunction exceptions

15-minute Block Averages and Complete Documentation of Algorithms for Compliance

The EPA requires key parameters to be measured and reported, including Net Heating Value of the combustion Zone (NHVcz), Net Heating Value Dilution Parameter (NHVdil) (when perimeter assist air is used), Flare Tip Velocity (Vtip), and Pilot Flame Presence and Visible Emissions (VE).

The operating limits for NHVcz, NHVdil, and Vtip are based on 15-minute block averages when regulated material is being routed to the flare for at least 15 minutes. These parameters are calculated from multiple monitored operating parameters including flows (cumulative), temperatures, pressures, and net heating value of the flare vent gas.

Managing this data can be challenging since compliance is determined at the end of each 15-minute block. This requires increased capabilities of the data acquisition system.

For each of these blocks, the EPA now also requires you to provide a copy of the data acquisition system algorithm used to reduce the measured data into the reportable form of the standard and to calculate the applicable averages.

The compliance average calculations must exclude invalid data (i.e., Out of Control, maintenance, CPMS breakdowns, calibration checks, etc.). You must state if the DAS algorithm handles this for you. If it doesn’t, then you must document your procedure for identifying and excluding this data.

StackVision excludes invalid data in real-time as it is acquired. It captures or determines status codes and provides a complete chain of all calculations, data handling, and reduction. System design reports plus full configuration control and transparency provide ease of documentation. It also allows users to annotate and edit data, with easy recalculation following updates.

Increased Quality Control Activities and Associated Recordkeeping

Adding equipment like flow meters, analyzers, temperature and pressure monitors to your monitoring requirements — sometimes in multiples if measuring different streams — is challenging.

Many refineries are opting to use a gas chromatograph or mass spectrometer to determine net heating value of the vent gas. If your refinery is using a gas chromatograph or mass spectrometer to determine net heating value of the vent gas and the daily calibration checks, using the modified PS-9 could be particularly difficult. Depending on your supplier, you may also have to use multiple bottles for each calibration check, to measure many gases.

The StackVision DAS provides tools dedicated to monitoring the status of your monitoring systems. Displays, reports, alarms, and notifications reduce downtime. They catch flatlining, target your maintenance efforts, and make recordkeeping and reporting simpler. StackVision provides a solution for test record management, cylinder gas management, and report generation. It can also run hands-off, automated calibration checks, which are much safer for the technicians.

Ready Access to Compliance Parameters for Operators

Per the EPA, values from monitored operating parameters must be readily accessible onsite for operational control or inspection.

The StackVision DAS offers many ways of supplying quality assured values to the operators. Quality assured values can be provided through displays or directly to the DCS and historian. You can send the quality assured values in real-time to the DCS, to let operators control flows manually or automatically.

StackVision can also provide alarms and notifications for monitoring system status. The alarms can be sent to the Environmental, Operations, Controls, or any combination of internal groups.

The Requirement to Report, Retain, and Make Data Available

Periodic reports include emergency flaring events and deviations from the allowed operating limits. To make these reports, daily or weekly reviews, logging, coding, and investigation are required. When it is time for submission there is more review and compilation. Moving large quantities of data from the historian into spreadsheets is a tedious and error-prone process.

All reported values must be retained for five years. However, the additional data you must retain includes a great deal of contextual information (see recordkeeping examples outlined in CFR Part 63), resulting large amount of information that presents a storage problem difficult to accomplish with spreadsheets. Additionally, all data must be available for inspection within 24 hours upon request during the stated period.

Using a DAS such as StackVision simplifies data review and reporting. Scheduled reports, displays, and automation let you focus on compliance, not bookkeeping. With StackVision, your data from five years ago is as accessible as data from yesterday.

Emergency Flaring Limits Include Startup, Shutdown, and Malfunction

The EPA’s emergency flaring provisions impose operating limits to make most flares behave like the best-performing flares. They exclude Force Majeure flaring events but, most other “emergency” flaring events that meet their criteria are considered preventable.

There is no leeway allowed for events determined to be caused by operator error or poor maintenance. These are automatic violations.

You need excellent monitoring and quality control to react to flaring events and minimize violations, as well as meticulous recordkeeping to avoid accusations of operator error or poor maintenance. ESC Spectrum’s StackVision provides the tools you need to track and prove compliance.

Learn More About Using StackVision for RSR Regulations

StackVision offers insights into your emissions and compliance that other software solutions simply can’t. We constantly work to keep up with changes in technology and regulations. Contact us today to see how StackVision can help your facility stay in compliance.